Overview

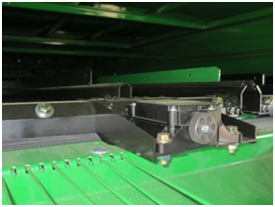

- Single-point feederhouse latching

- Mass-flow sensor

- Reel resume in-cab control

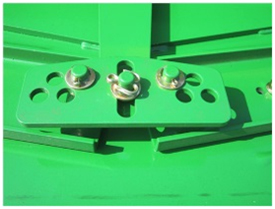

- Easily remove fingers at rear of chaffer

Features

Features

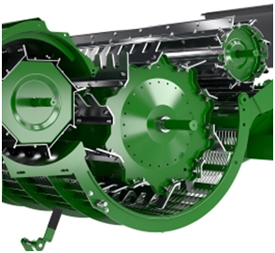

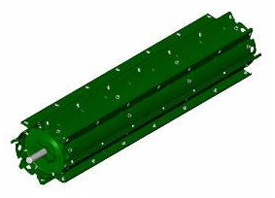

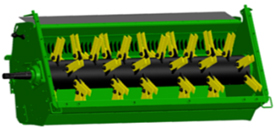

Threshing and separating concept

Threshing and separation concept of T-Series

Threshing and separation concept of T-Series

Functional components:

- Large, 660-mm (26-in.) diameter threshing cylinder with 10 rasp bars and increased concave area

- Smooth stripper roll and enlarged overshot beater

- Enlarged, 800-mm (31.5-in.) separator with high-performance separation grate

- Eight-wing, 400-mm (15.7-in.) rear beater and rear beater grate

- Seven-step straw walker design with welded or optional bolted universal and corn-cob mix (CCM) grids

- Sectional concave with quick adjustable de-awning plates

Large, 660-mm (26-in.) threshing cylinder with 10 rasp bars and enlarged concave

The large, 10-rasp bar threshing cylinder with 660-mm (26-in.) diameter provides excellent grain quality and gentle material handling.

Combined with the enlarged wrapping angle of 124 degrees, this ensures excellent threshing efficiency, providing unmatched capacity even in tough separating conditions.

Four rasp bars are in constant contact with the crop against the concave area for excellent threshing and separating efficiency:

- Provides a large concave area and allows a slow cylinder speed

- Ensures gentle threshing and separation to reduce grain damage

- Large, concave wrapping angle ensures high grain separation right at the beginning and reduces separation load on the straw walkers

- Wide, 1670-mm (65.7-in.) (6-Walker) channel width grants maximum throughput even in tough separating conditions

Stripper drum and overshot beater

Stripper drum

Stripper drum

Overshot beater

Overshot beater

The T-Series threshing system uses a smooth surface stripper roller behind the threshing cylinder to gently direct the material to the overshot beater. This prevents material from back feeding on the threshing cylinder, eliminating blockages of the cylinder. The stripper roller speed runs at 125 percent ratio of the threshing cylinder speed.

The 500-mm (19.7-in.) overshot beater on the T-Series continues the material flow process. Material travels over the top of the beater and is directed into the separation drum.

Smooth crop flow is achieved without harsh angles or abrupt changes in direction.

The eight-wing beater has a constant speed. The serrated design of the wings’ leading edges engage the mat of material and move the high volumes of tough, damp straw without buildup or bunching.

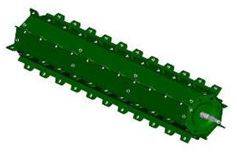

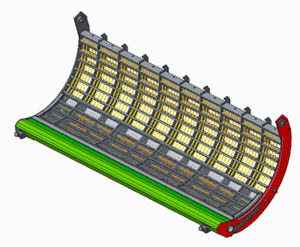

Extra-large separator and dynamic tangential grate

Extra-large separator and dynamic tangential grate

The 800-mm (31.5-in.) extra-large separator drum provides additional separation capacity or the T-Series. Due to the open design, the drum is not heavier in weight than the previous closed design.

The extra-large separator drum runs at two factory-installed speeds:

- 760 rpm for small grain and grass seed

- 380 rpm for canola, peas, and beans

There is an optional 270 rpm speed reduction kit available for corn harvest which is included in the corn package. Swapping the belt speed can be done easily and quickly by changing the drive pulley via a lever-operated tension pulley.

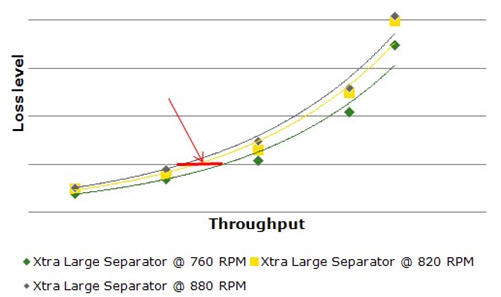

The extra-large separator drum runs at a lower speed compared to the previous design that was operated at 900/450 rpm. While it seems that higher drum speeds result in more efficient separation capacity caused by the higher centrifugal force, the opposite effect has been measured. While the centrifugal force has a vital impact on the separation capacity, speeds of the separator drum that are too high result in low exposure time in the high-performance separator grate. This is shown in the graph below.

Comparison of separator speed

Comparison separator speed

Comparison separator speed

The red line indicates the performance delta at a loss level of one percent between the different separator speeds.

The dynamic tangential grate (new beginning in model year 2019) features a completely updated design equipped with a full wire profile as described below.

Dynamic tangential grate

Dynamic tangential grate

For model year 2019, the design was changed for fewer restrictions on crop flow and optimal separation that would not affect straw quality.

- All the transversal bars are produced with round edges for better crop flow and straw quality.

- All the wires are repositioned as close to the upper edge as possible to prevent any straw accumulation, therefore improving separation capacity.

- The wires are implemented on the complete area and replace finger rakes for larger opening areas (+10 percent opening area versus model year 2016 tangential grate).

Rear beater and rear beater grate

Rear beater

Rear beater

The 400-mm (15.7-in.) rear beater on the T-Series continues the material flow process. The beater delivers material to the straw walkers. The beater is driven directly from the extra-large separator drum and is operated at two speeds.

- 900 rpm for small grain and grass seed

- 450 rpm for rape seed, corn, peas, and beans

A separation grate is mounted underneath the rear beater. The grate is adjustable with a handle on the right side.

Two positions are available:

- Wide position recommended in rape seed, corn, peas, beans, or other sensitive crops

- Narrow position for small grain or grass seed

Inside the T-Series threshing and separation system is an eight-winged, rear beater drum that separates the remaining grain out of the straw mat. The rear beater grate provides additional active separation area.

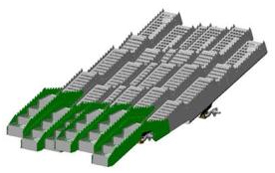

Straw walker concept

Seven-step straw walker design

Seven-step straw walker design

The T-Series has a seven-step straw walker concept. Compared to the previous T-Series, the model year 2017 and newer T-Series straw walker is extended by 80 mm (3.15 in.), which results in a slightly increased overall straw walker area (+ 0.1 m² [1.08 sq ft]). The concept of low walker rpm and high walker stroke provides efficient tossing to fluff even largest straw mats and open channels for the free grains to drop through. This results in most efficient grain separation capability. The straw walker is available with welded or bolted universal and CCM grids for best-in-class reconfiguration and ability to retrofit for all crops and conditions.

The straw walker is equipped with a closed walker trough at the rear, which ensures the grain is captured in the trough and feeds evenly on the walker return pan that is mounted below the front section of the walkers. Section dividers on the return pan help to maintain an even distribution of material onto the front chaffer of the cleaning system, even on slopes.

- High throw provides efficient tossing to fluff even the largest straw mats and open channels for the kernels to drop through.

- Maximum grain separation is achieved at the front section due to the impact of the straw mat when hitting the first walker steps.

- Four shallow, angled steps provide maximum separating efficiency.

Different walker grids are available to match all crop and conditions.

Overall threshing and separation system benefits:

- Greater level of productivity due to the enlarged concave wrapping angle, extra-large separator drum, and the high-performance separator grate

- Best-in-class grain and straw quality can be achieved with the threshing and separating concept

- Fast and easy adoption for different crops

- Lower power consumption and excellent straw quality, making this combine the optimal choice for straw producers

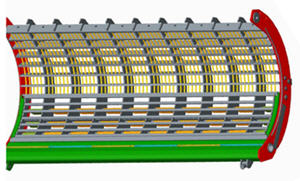

Sectional concave with quick adjustable de-awning plates

Sectional concave with small-grain inserts

Sectional concave with small-grain inserts

Feature benefits:

- High versatility and flexibility with three different concave inserts available

- Uptime ensured with fast exchange design

- Easy access from stone trap and storage position for the concave inserts

Theory of operation

Versatility on a combine is increasingly important as producers have to handle multiple crops, sometimes changing between crops during the day.

The threshing needs are very different from crop to crop. Coarse grains like corn or peas require a round bar profile that is less aggressive to ensure optimal grain quality. Small grains including grass seed, vegetables seeds, and durum wheat need intensive threshing and require a small-grain concave profile which provides aggressive threshing to separate the grain.

The sectional concave is made with a fixed concave associated to a removable design on the front where the threshing begins.

Producers will have the possibility to install three different concave profiles:

- Small-grain concave inserts

- Universal concave inserts

- Round-bar concave inserts

- Sectional concave with round-bar concave inserts

Producers can exchange the concave inserts in 15 to 20 minutes by opening the stone trap.

A screw is available on the left side and will maintain the concave inserts in the working position. When the operator loosens the screw, he can easily remove the two inserts and replace them with another set of inserts.

On the right side, the operator has the capability via a screw to install or remove the swing in/out booster bar.

The machine will be delivered with small-grain inserts installed and can receive additional universal inserts as factory installed (in storage) or round-bar inserts as dealer installed.

More cleaning system capacity with the Dyna-Flo™ Plus cleaning shoe

Remote adjustment of Dyna-Flo Plus cleaning system

Remote adjustment of Dyna-Flo Plus cleaning system

The Dyna-Flo Plus cleaning system comes standard with electric adjustment on all T670 Combines.

The remote cleaning shoe adjustment can be either completed from inside the cab on display settings or with the armrest buttons. As an alternative solution, such as when inspecting the shoe from the outside, settings can also be adjusted from the left side at the rear of the machine.

The remote cleaning shoe adjustment motors are equipped with an integrated position sensor. This eliminates the need for recalibration of the electric motors. Calibrations only need to be redone in case the electric hardware or the cleaning shoe elements get replaced.

4813 |

Remote cleaning shoe adjustment

Dyna-Flo Plus cleaning shoe |

Corn package

Corn harvest

Corn harvest

Corn harvest

Corn harvest

When harvesting corn grain, quality is key. The threshing and separating process must be done extremely gently and all crop-engaging components must be operated at lower speeds. The corn package includes a wide range of speed reduction components such as the 15/33 feederhouse speed-reduction sprocket and T-separator speed reduction, which guarantees excellent grain quality even under dry conditions.

A brush sealing kit comes installed on the side panels around the cleaning shoe fan air inlet. This prevents corn leaves from being sucked into the cleaning shoe where they potentially can plug the louvers and cause insufficient cleaning shoe performance resulting in dirty grain tank samples or high grain losses.

The dual-range cylinder drive must be ordered in combination with the corn package and is dealer-installed.

Drive parts to slow down the unloading auger come by-packed and are especially recommended in high-moisture corn harvest (more than 32 percent moisture) to reduce the risk of unloading auger blockage or premature shear bolt failure. For dry corn harvest (below 32 percent moisture), the unloading rate can be reduced by adjusting the grain tank cross auger covers to a lower position (please refer to the operator’s manual).

To avoid damage on the straw chopper, the dual-range chopper drive must be ordered in combination with the corn package and is dealer-installed. To avoid further damage at the chopper housing and the straw hood, a cob deflector plus stationary knife cover comes by-packed with the machine.

To prevent damage on the chaff spreader disk or housing, a speed reduction valve comes installed when the corn package is ordered. This reduces the chaff spreader speed.

Option code |

Description |

4211 |

Corn package NOTE: Requires dual-range cylinder drive – code 4420. NOTE: Requires dual-speed straw chopper drive – code 8570. |

The clean-grain elevator can be equipped with stainless-steel paddles for reliable clean-grain transportation and a slip clutch to prevent blockage inside the housing or elevator chain/drive belt damage due to the higher amount of grain. This slip clutch is strongly recommended in wet harvesting conditions (above 32 percent grain moisture) and needs to be ordered separately.

Option code |

Description |

8526 |

Clean-grain elevator slip clutch |

Factory installed:

- Dual-range cylinder drive

- Dual-speed chopper drive

- Chaff spreader speed reduction valve

By-packed:

- Feederhouse speed reduction sprocket 15/33

- Stone trap cover plate

- Cylinder filling plates

- Unloading auger speed reduction sprockets

- Cleaning shoe fan air inlet brush kit

- Corn cob deflector for rear hood (fine-cut and extra-fine cut chopper)

- Counter knife cover (fine-cut and extra-fine cut chopper)

- Extra-large separator speed reduction (T-Series only)

NOTE: Code 8526 clean grain elevator slip clutch is highly recommended for wet corn harvest (more than 32 percent moisture) – not included in corn package.

Pre-selection when corn package is ordered:

- Dual-speed cylinder drive (code 4420)

- Dual-speed chopper drive (code 8570)

To ensure excellent cleaning shoe performance of the Dyna-Flo™ Plus cleaning system, a wide range of cleaning shoe elements are offered that are specially designed for corn harvest.

The premium corn cleaning shoe elements ensure excellent cleaning shoe performance in dry or medium moisture conditions, which results in excellent grain tank quality. In high-moisture conditions, they avoid plug-in of louver elements, which ensures the machine keeps harvesting and eliminates the need for the operator to stop the machine and clean the chaffer elements to avoid excessive grain losses.

The corn cob mix (CCM) frog-mouth elements provide a wide 80-mm (3.1-in.) opening, enabling a big portion of the cobs to pass the chaffer element and be collected in the grain tank.

The tailings cover kit is required when the machine is operated without a lower sieve.

Grass package for walker combines

Grass seed

Grass seed

Grass field

Grass field

Harvesting grass seed requires optimum air flow distribution resulting in excellent cleaning shoe performance as the very light grass seeds are extremely sensitive to uneven air flow. This causes either losses by being blown out the back or shaken out in case they come in direct contact with the louver elements.

The grass package must be ordered with the dual-range fan drive that reduces the fan speed range down to 300 rpm, which is zero to none especially for extremely light seed varieties such as grass seed.

To ensure optimum grain handling, the grass package must be ordered with the grain elevator slip clutch, including steel paddles. The steel paddles whip out the elevator housing and ensure crop does not accumulate, especially when doing straight-cut grass harvest where moisture might be higher. The grain elevator slip clutch avoids premature belt or drive component failure.

A U-joint paddle comes installed on the transition housing of the grain-tank filling auger, which ensures active material conveyance and avoids risk of accumulation and plugging of the grain-tank filling auger.

The vertical unloading auger inside the grain tank is factory installed as rice auger version. The auger has thicker flights, ensuring maximum lifetime and avoiding the bending of auger flights which could cause a blockage of the entire unloading auger.

As the quick-adjustable auger covers must be set at a very high position, especially in higher moisture grass seed, it is strongly recommended to install the by-packed unloading auger speed reduction sprockets.

Factory installed:

- Unloading auger as rice version with double flight thickness (code 8530)

- High-moisture grain handling system (code 8523)

- Clean-grain elevator slip clutch

- Dual-range fan drive

- Clean grain elevator to filling auger U-joint paddle

By-packed:

- Unloading auger speed reduction sprockets

Pre-selection when grass package is ordered:

- Clean grain elevator slip clutch (code 8526)

- Dual-range fan drive (code 8405)

Faster crop-to-crop changeover

Quick-engage booster bar

Quick-engage booster bar

Quick-engage booster bar adjustment

Quick-engage booster bar adjustment

The quick-engage booster bar is adjustable from the outside via the stone trap with a 24-mm (0.95-in.) wrench. It has two positions. In the engaged position, the concave entrance features a profiled rasp bar. In the disengaged position, the concave entrance features a smooth transition plate. Adjustment can be completed easily within minutes.

Material flow coming from the feederhouse passing the booster bar is slowed down; this increases the threshing efficiency. The booster bar does not have a negative influence on the crop flow or the grain quality. The booster bar increases threshing efficiency in hard-to-thresh crops without closing the de-awning plates, allowing maximum separation at the concave area.

NOTE: The booster bar is standard on the T670.

8449 |

Quick-engage booster bar |

Extra-fast unloading system

The fast unloading system of the T670 provides a rate of 125 L/sec (3.3 bu/sec). Compared to the previous unloading system, this ensures an unloading rate that is 50 percent faster and is reflected as a time saving when unloading on the headland.

The higher unload rate is achieved by grain tank cross augers, an increased discharge housing including vertical auger, and an overall higher speed of the unloading system.

Enhanced extra-fine-cut residue system

Extra-fine-cut chopper rotor and housing

Extra-fine-cut chopper rotor and housing

The improved extra-fine-cut straw chopper delivers excellent chopping quality and best-in-class residue distribution of chopped material in the field with a cutting width up to 10.70 m (35 ft).

The extra-fine-cut chopper comes standard with serrated chopper knives, which ensure superior splicing of the straw and improved straw rotting process. The extra-fine-cut chopper is highly recommended for producers with no tillage or minimum tillage operations.

The optional dual-speed chopper drive provides flexibility to match all crops and conditions.

5771 |

Extra-fine-cut chopper with serrated knives, remote adjustable tailboard, and factory-installed wind paddles |

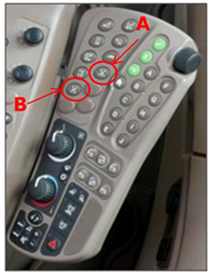

Armrest adjustment

Armrest adjustment

The extra-fine-cut chopper comes standard with a remote adjustable tailboard.

The remote adjustable tailboard can be adjusted from the cab conveniently via armrest control buttons (button A). The in-cab adjustment includes a unique tailboard position swap button (button B); by pressing the button on the armrest, the tailboard vanes automatically swap from left to right stored position and vice versa.

False floor geometry housing

The extra-fine-cut chopper housing follows the contour of the rotating knifes. This false floor geometry narrows the gap between the rotating knife and the chopper housing to a 4–5 mm (0.16-0.20-in.) closing at a wrapping angle of 83 degrees. It requires no adjustments and does not require any maintenance or replacements.

Wind paddle

The T670 with extra-fine-cut chopper comes standard equipped with wind paddles, which are factory installed on two knife rows. The wind paddles are mounted with bushings to withstand impacts from foreign objects. Equipped with wind paddles, the extra-fine-cut chopper is able to spread the chopped straw evenly up to 10.70 m (35 ft). Wind paddles are more effective than active radial spreaders, which are normally hydraulically driven.

Windrow sheet

Windrow deflector plate

Windrow deflector plate

Straw chopper clutch

Straw chopper clutch

A single lever operates the windrow deflector plate. Operated on the right side, the straw is guided into the chopper or down on the ground for windrowing.

The straw chopper is directly driven from the main engine gearcase and automatically engages with the separator drive. A heavy-duty power belt reliably transmits drive power to the chopper. A reliable clutch is used for engaging and disengaging the chopper rotor.

Counter knives

Counter knives adjustment

Counter knives adjustment

The extra-fine-cut chopper comes standard with a counter knife row, which is infinitely adjustable with two large leavers on each side. To secure the position, only one bolt needs to be tightened at each side.

Grouser bar

Grouser bar adjustment

Grouser bar adjustment

The extra-fine-cut chopper features a redesigned grouser bar, which is infinitely adjustable with a slide bar. To reduce the length of chopped material in green straw conditions, the grouser bar should be engaged. In dry straw conditions, it improves the splicing of the straw. To decrease fuel consumption, it is recommended to remove the grouser bar when chopping other crops such as corn, rape seed, beans, peas, and sunflower.

Tailboard angle adjustment

Tailboard angle adjustment

Tailboard angle adjustment

Tailboard vane adjustment

Tailboard vane adjustment

The tailboard angle can be adjusted without tools in three positions with a lever on each side.

In addition to the three-point tailboard adjustment, the vane angle can be set in four additional positions to ensure the spreading width of the residue matches all cutting platforms up to 10.70 m (35 ft).

The extra-fine-cut chopper comes standard with a 10-vane electrical tailboard design.

On-board air compressor

Air compressor engagement button

Air compressor engagement button

To improve serviceability and cleaning of the entire combine after a long and dusty working day, a factory-installed air compressor is available as an option.

The air compressor features three air take-off couplers: one on the left side near the toolbox compartment, one on the right side below the fuel tank, and one on the engine deck. With a 10-m (32.8-ft) hose, an additional air pistol, and a 125-cm (49.2-in.) lance, each point on the machine can be reached comfortably, easily, and quickly.

The air connection valve is activated with the air compressor engagement button on the armrest. Air can be used via the quick couplers. The air compressor engagement button can be activated when the machine is not moving, the separator is disengaged, and the park brake is activated.

Once the air compressor is engaged by a button on the armrest, the system starts to fill the 60-L (16-gal.) air reservoir tank until a shut- off pressure of 8 bars (116 psi) is reached. The system automatically stops to ensure power is only consumed if necessary.

NOTE: The air compressor option has not been optimized for operation of air tools and is not recommended to blow out engine air filter or debris management filter with the engine in operation.

NOTE: It is recommended to drain moisture from the air tank daily when the machine is in use to prevent degradation in the performance of the system. When servicing the air compressor, it is recommended to expel all stored air from the system.

8649 |

Air compressor

Factory installed |