Overview

- 60-ft. toolbar with 24 rows on 30-in. spacing

- Available in mini-hopper MaxEmerge™ 5 row unit

- Insecticide option for mini-hopper

- Requires a minimum 235-hp tractor equipped with Category 4 drawbar

Features

Features

Monitor planter performance in the cab

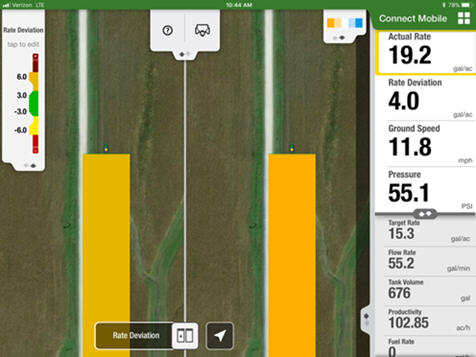

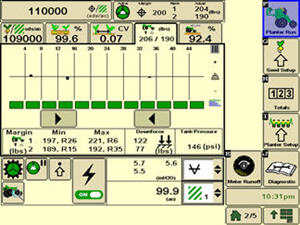

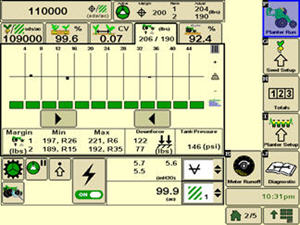

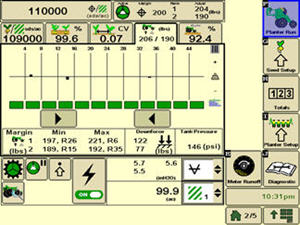

Connect Mobile showing a singulation map and monitoring planter performance

Connect Mobile showing a singulation map and monitoring planter performance

Connect Mobile overview

John Deere Connect Mobile is a solution that utilizes an Apple® iPad® in the cab that provides the operator a better understanding of the planter’s performance. Connect Mobile documents and displays the row-by-row performance of the planter, helping the operator monitor and more easily detect problems that can occur while planting. Connect Mobile also has a common user interface that makes it easy to use between different pieces of John Deere equipment. Once the job is done, the iPad with the planting data can be utilized to perform basic crop scouting activities in the field.

Planting attributes

Monitor and document key performance indicators in high-definition map layers and dashboard tiles such as:

- Actual population

- Target population

- Singulation

- Seed-spacing CV

- Applied down force

- Gauge wheel margin

- Ride quality

- Ground speed

- Variety

In base equipment

Connect Mobile hardware is factory installed on all model year 2015 and newer planters factory installed with ExactEmerge™ row-units and all model year 2017 and newer planters factory installed with MaxEmerge™ 5e row-units, making it easy to get started with Connect Mobile.

Learn more about Connect Mobile in the Field and Crop Solutions section within the Precision Ag Technology product line and how it can improve the quality of a planting job.

iPad and Apple are trademarks of Apple Inc.

Innovative Central Insecticide System (CIS)

The CIS is designed to work with Force® CS, which is an improved soil-applied insecticide designed to deliver consistent performance in an advanced, convenient liquid formulation.

The innovative design of the CIS incorporates many user-friendly features such as closed handling, central fill, direct injection, and industry-leading row-to-row accuracy. CIS is available on the following models with Pro Series™ row units only, and can be only ordered as an aftermarket field conversion attachment:

- 1775NT Central Commodity System (CCS™) - 12 row

- 1775NT CCS – 16 row

- 1775NT CCS – 24 row

- 1795 - 12/23Row and 12/24 row

- 1795 - 16/31Row and 16/32 row

- DB60 - 47 row 38 cm (15 in.)

- DB80 - 32 row 76 cm (30 in.)

- DB90 - 36 row 76 cm (30 in.)

Force CS

For more than 20 years, growers have trusted the performance of Force 3G for superior control of corn rootworms, as well as troublesome early-season pests. Now, with Force CS, growers can achieve the same top-rated performance they have come to expect from Force 3G in an easier to use liquid formulation. Force CS will be packaged in a unique patent-pending box. Each box contains 9.4 L (2.5 gal.) of Force CS and will treat approximately 16 ha (440 acres).

System components

The CIS consists of six major components:

-

Insecticide cabinet

-

Water tank(s)

-

Pump and valve assembly

-

Flow monitors

-

Nozzles

-

Controller/monitor

Insecticide cabinet

Insecticide cabinet - loaded with Force CS

Insecticide cabinet - loaded with Force CS

The insecticide cabinet, which is manufactured from the same material as the CCS tanks, is designed to hold a maximum of eight boxes of Force CS. Each Force CS box contains 9.4 L (2.5 gal.) of product for a total system capacity of 76 L (20 gal). This 76 L (20 gal.) of Force CS allows the operator to cover 256 acres between fills if the full rate (10 oz/acre for 76-cm (30-in.) rows) of Force CS is applied for all rows. The coverage acres increase if product is only applied to the designated refuge rows.

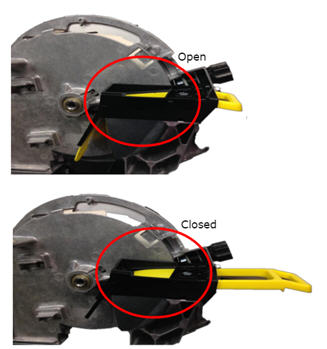

Connectors and in-line check valve

Connectors and in-line check valve

After the desired number of Force CS boxes are placed in the cabinet, the operator connects the Force CS box to the CIS system by using a connector (shown on the left). This connection device drastically reduces the amount of exposure compared to granular-type insecticide systems.

The system is also designed to empty the boxes from the top down. Product from the top boxes will empty before the system starts to pull product from the next row. This is possible by utilizing a check valve on the last product box (shown on the left).

Water tank

300-gal. tank on 1775NT 16Row

300-gal. tank on 1775NT 16Row

The CIS utilizes direct injection technology to move ounces of the Force CS product into water; therefore, every CIS requires an appropriately-sized water tank to supply the pump and valve assembly for Force CS application. Below is a chart with planter model, tank sizes, and acres covered.

Planter model |

Water capacity |

Acres/fill (water) |

Acres/fill (insecticide) eight-box cabinet |

Rate = 2 gal./acre |

Rate = 10 oz/acre |

||

30-ft 1795 |

852 L (225 gal.) |

46 ha (113 acres) |

104 ha (256 acres) |

40-ft 1795 |

1060 L (280 gal.) |

57 ha (140 acres) |

104 ha (256 acres) |

12-row 1775NT CCS |

852 L (225 gal.) |

46 ha (113 acres) |

104 ha (256 acres) |

16-row 1775NT CCS |

1136 L (300 gal.) |

61 ha (150 acres) |

104 ha (256 acres) |

24-row 1775NT CCS |

1703 L (450 gal.) |

91 ha (225 acres) |

104 ha (256 acres) |

DB60 |

1590 L (420 gal.) |

85 ha (210 acres) |

104 ha (256 acres) |

DB80 |

1590 L (420 gal.) |

85 ha (210 acres) |

104 ha (256 acres) |

DB90 |

1590 L (420 gal.) |

85 ha (210 acres) |

104 ha (256 acres) |

NOTE: Depending on model, water capacities may be reduced when equipped with Refuge Plus.

Pump and valve assembly

Pump and valve assembly

Pump and valve assembly

3-section valves

3-section valves

The pump and valve assembly consists of a hydraulically driven water pump, electric injection pump, and section valves. The hydraulic water pump is tied into the frame hydraulics and does not require an additional selective control valve (SCV). The electric injection pump pulls product out of the Force CS boxes and injects the product into the waterline, which then enters a mixing chamber where the water and Force CS are thoroughly mixed together.

The CIS system features a closed calibration procedure to protect the operator from insecticide exposure. Comparable granular type insecticide systems require the operator to collect chemical from each row unit on the planter, while the CIS closed calibration is performed at one central location and does not require the operator to measure any product, dramatically eliminating exposure to insecticide.

One of the many features of the CIS is the ability to apply insecticide on refuge rows only. From the tractor cab, the operator can set the monitor to apply insecticide to refuge rows only. This makes the CIS a perfect fit with Refuge Plus. When refuge only is selected on the monitor, the CIS will only apply insecticide on the designated refuge rows. These rows are predetermined from the factory and are listed below for each model.

| Model | Refuge rows |

1775NT CCS - 12row |

10, 11, 12 |

| 1775NT CCS - 16row | 13, 14, 15, 16 |

| 1775NT CCS - 24row | 20, 21, 22, 23, 24 |

| 1795 - 12/23row | 19, 21, 23 |

| 1795 - 12/24row | 20, 22, 24 |

| 1795 - 16/31row | 25, 27, 29, 31 |

| 1795 - 16/32row | 26, 28, 30, 32 |

| DB 60 | 20, 21, 22, 23, 24 |

| DB 80 | 14, 15, 16, 17, 18, 19, 20 |

| DB 90 | 15, 16, 17, 18, 19, 20, 21, 22 |

While the ability to apply Force CS to refuge rows is a unique feature, CIS can easily distribute product to every row across the entire planter width. Application setup is simple and is completed through the system monitor/controller.

Flow monitors

Flow monitors

Flow monitors

Flow monitors are mounted on the wings to provide operator confidence and peace of mind that each row is receiving an equal amount of product. When operating, the orange balls within the flow monitors will be suspended in the middle of the site glass. If a nozzle or delivery line becomes restricted or becomes damaged, the flow monitor will indicate this under or over application.

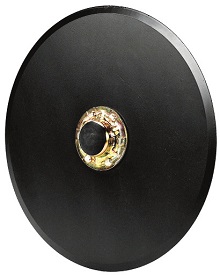

Nozzles

Nozzle

Nozzle

The CIS system utilizes a 0067 SprayMasterTM nozzle to apply the Force CS in 13- to 20-cm (5- to 8-in.) T-band over the seed furrow. This nozzle is located between the double disk openers and the closing wheels. When not in use, a nozzle cap is provided to replace the nozzle protecting it from wear.

Applying Force CS in a T-band pattern is the only approved application method. Spraying the product in a T-band ensures proper application and seed/soil coverage. The supplied 0067 SprayMaster nozzle is not compatible with any length of aftermarket seed firmer due to spray interference. If the planter is equipped with short seed firmer, a separate flat fan nozzle and adapter should be used.

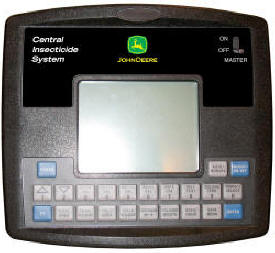

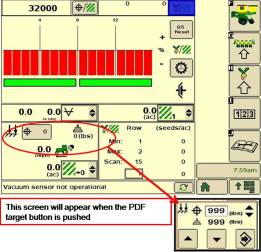

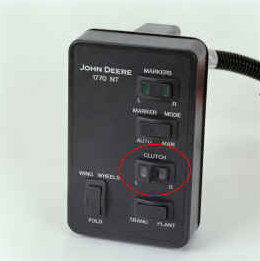

Monitor

CIS monitor

CIS monitor

CIS utilizes a separate, independent monitor that also acts as the system controller. The monitor is capable of controlling two separate products at the same time (water and Force CS) and is compatible with GreenStar™ (GS) 2 Field Doc™ connect. This monitor is specific to the CIS and will not work with any other applications.

The monitor conveniently displays product application rates, acre totals, and product/acres remaining. System setup, product and water rates, as well as priming are initiated from the controller/monitor. CIS is completely integrated with the planter design. CIS automatically shuts off product flow when the planter is raised and is also tied to the seed meter one-half or one-third width disconnect.

System cleanout

CIS end-of-season cleanout and winterization is simple to perform. CIS will draw John Deere winterizer fluid (part N305643 or equivalent) through the system and residual Force CS with winterizing fluid solution will be captured in an enclosed container for proper disposal. Follow all label instructions for proper handling and disposal procedures.

IMPORTANT: Always read and follow label directions before buying or using this product. Force CS is a restricted-use pesticide.

Force® CS is a trademark of a Syngenta Group Company.

SeedStar™ XP monitoring system

SeedStar XP overview

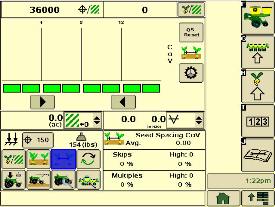

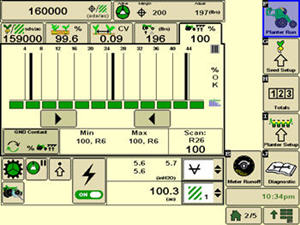

SeedStar XP shown on the GreenStar 3 2630 Display

SeedStar XP shown on the GreenStar 3 2630 Display

SeedStar XP shown on the GreenStar 2 1800 Display

SeedStar XP shown on the GreenStar 2 1800 Display

Building upon the foundation of SeedStar 2, the SeedStar XP system takes planter monitoring to the next level. When paired with the GreenStar™ (GS) displays (GS 2600 or 2630 Display or the entry-level GS2 1800 Display), the SeedStar XP monitoring system provides more information about the planting process to the operator within the tractor cab.

Specific information about how the planter is performing enables the operator to make needed adjustments for implement optimization.

The SeedStar XP planting functions are fully integrated with the full spectrum of AMS applications such as Swath Control Pro™ system for planters, GreenStar AutoTrac™ assisted steering system, John Deere Operations Center, documentation, and others. Integrated planting technologies, for better asset utilization and ease of use, is just part of what SeedStar XP provides.

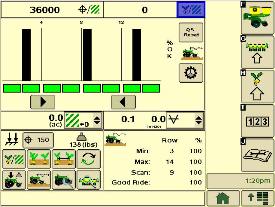

SeedStar XP seed singulation monitoring

SeedStar XP seed singulation planter run page

SeedStar XP seed singulation planter run page

Understanding the meter singulation performance on the planter is critical to minimizing the amount of seed multiples and skips. As a result, the SeedStar XP monitoring system provides real-time information from the row-units about the overall seed singulation performance.

As seen in the screen shot image above, seed multiple information is displayed on the top portion of the planter-at-a-glance bar with seed skip information on the lower portion. This provides the operator a better understanding of relative seed multiple and skip data on a row-unit basis; all within one easy glance.

Also, within the seed singulation planter run page, information about row-units with the highest percentage of seed multiples and skips is provided in order to make necessary adjustments for better planter optimization.

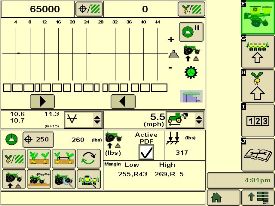

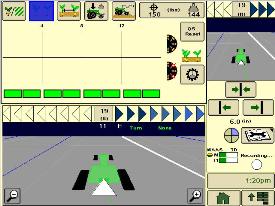

SeedStar XP row-unit ride dynamics planter run page

SeedStar XP ride dynamics planter run page

SeedStar XP ride dynamics planter run page

While operating a planter, travel speed and field conditions can affect the amount of row-unit bounce that is experienced. Excessive row-unit bounce or vertical motion can cause problems with meter performance. To better understand the amount of row-unit vertical motion when travelling through a field, the SeedStar XP monitoring system provides real-time information on row-unit ride dynamics.

As seen in the ride dynamics planter-at-a-glance screen shot image above, the SeedStar XP system provides ride dynamic information for each sensor node that is mounted on the planter. Each sensor node transmits ride dynamic information for each planter frame section to allow for the operator to make necessary operating adjustments to improve overall planting performance.

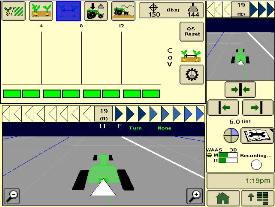

SeedStar XP row-unit downforce planter run page

SeedStar XP downforce planter run page

SeedStar XP downforce planter run page

As row-unit downforce systems gradually change from heavy-duty downforce springs to pneumatic downforce, being able to understand the amount of as-applied row-unit downforce is needed while operating the planter.

With various soil conditions, moisture, etc. experienced while planting, it is imperative to have the ability to change actual row-unit downforce to have enough force for the Tru-Vee™ openers to penetrate the soil media. However, in some conditions, having too much downforce applied to the row-units for effective opener penetration could cause problems with side wall compaction from the gauge wheel.

Side wall compaction within the seed furrow can cause hatchet roots to develop; or roots that do not have the ability to penetrate the seed furrow soil media. This could lead to poor plant emergence and eventually lower overall yield performance.

With the SeedStar XP monitoring system, row-unit downforce information is measured by the downforce sensor and sensor nodes and transmitted to the GreenStar 2 (GS2) Display in the tractor cab (as seen in the image above). The row-unit downforce information is displayed on the top portion of the planter-at-a-glance bar with more row-unit downforce information on the lower portion.

Two different control options are available on 1775NT, 1795, and DB Series Planters for pneumatic downforce. The base pneumatic downforce system requires manual control of the downforce to maintain the desired planting results or row-unit margin. Optional active pneumatic downforce takes SeedStar XP even further by removing constant downforce adjustments from the operator and actively controlling the downforce system to maintain a desired target margin.

SeedStar XP seed spacing monitoring

SeedStar XP seed spacing planter run page

SeedStar XP seed spacing planter run page

Throughout the planting process, obtaining good seed spacing is critical toward achieving plant growing conditions for maximum yield potential.

Today, many items are adjusted on the planter prior to planting to optimize overall seed spacing performance. After such adjustments are made, information about the actual seed spacing performance during planting was missing within the planter monitoring system. Now with SeedStar XP, seed spacing information is transmitted live via the GreenStar display to show the operator exactly what is happening with the planter behind them.

The SeedStar XP transmits seed spacing information onto the planter-at-a-glance bar for easy understanding of planter seed spacing performance. Also, information about seed skips and multiples is provided to help understand actual planter meter performance and other related system functions in order to make necessary adjustments if needed.

NOTE: Seed spacing and seed singulation information is only available when planting crops with seed drop rates below 40 seeds/second such as corn. With higher population crops such as soybeans the system does not provide spacing and singulation information because the number of seeds dropping per second is much higher.

SeedStar XP full planter performance page

SeedStar XP planter details

SeedStar XP planter details

With the capability of monitoring differences in planting performance items such as seed singulation and row-unit downforce, having one screen to view all planter performance elements is needed to understand the whole planting system. SeedStar XP combines all of the various planting performance elements into one full-color, planter overview screen to enable for a quick understanding of relative planting functionality.

SeedStar XP half screens and other features

SeedStar XP seed singulation half screen

SeedStar XP seed singulation half screen

SeedStar XP seed spacing half screen

SeedStar XP seed spacing half screen

Other SeedStar XP monitoring features include:

- Capable of monitoring individual row-unit and overall planter performance in terms of seed spacing, singulation, and row-unit downforce

- Split-screen applications to enable use of popular guidance features such as AutoTrac™ assisted steering system

- On-screen indication of sensor node/downforce sensor assemblies once configured within the monitor settings application

- Full-color display icons for easy recognition and overall aesthetics

- Pneumatic downforce system controls with the GS Display application

SeedStar 2 monitoring original features

SeedStar XP retains all of those SeedStar 2 features that producers value and have come to expect:

-

Planter-at-a-glance. Allows operator to view relative population levels of all rows on one screen.

-

Automatic valve calibration. With the SeedStar variable rate drive (VRD), this is now completed automatically. There is no longer a need to manually calibrate the hydraulic valves.

-

Increased population updates. SeedStar will now update population levels once per second at planter start up then approximately once every three seconds.

-

Mapping of actual seed rates. When combined with documentation, actual and target seeding rates can now be mapped in John Deere Operations Center.

-

Reprogrammable utilizing controller area network (CAN) via Service ADVISOR™ diagnostics system.

-

Improved diagnostics/event recorder. On SeedStar variable-rate drive (VRD) planters, additional diagnostic information is available, as well as an event recorder to capture system performance data at a specific point in time.

-

Ability to run motors at different population levels. On SeedStar VRD, operators running multiple motor systems can run each motor at a different speed, allowing different population levels within a planter.

-

User-configurable high fertilizer pressure alarm. Allows the operator to be warned when fertilizer pressure reaches a specific level.

-

Automatic quick-start for SeedStar VRD. No longer does the operator need to press the quick-start button on end row turns to resume planting.

-

Automatic tractor speed source selection. When equipped with an 8000/9000 Series Tractor, the system selects the radar speed or allows for manual speed input selection.

Components and operation

Planter main 2 controller

Planter main 2 controller

Sensor node assembly installed

Sensor node assembly installed

The SeedStar XP monitoring system contains the following components in order to support the planting data transfer to the GS2 Displays:

- Seed monitor/variable-rate (SMVR) controller with model year 2011 or newer software

- Planter main 2 controller (installed on all SeedStar XP eligible models for model year 2011 or newer)

- Sensor node(s)

- Downforce sensor assembly

The planter main 2 controller processes the row-unit data from the sensor node assemblies located on the row-unit head casting. The processed information is then sent to the SMVR controller to be integrated into the displayed information being sent to the GS Display.

Downforce sensor assemblies are found on row-units with sensor nodes installed. The downforce sensor assembly is assembled with the gauge wheel depth-adjustment handle and provides gauge wheel pressure information to the respective sensor node for data processing.

Downforce sensor installed

Downforce sensor installed

Downforce sensor assembly

Downforce sensor assembly

Depending on the planter size, different configurations of sensor nodes and downforce sensors are installed in support of the SeedStar XP monitoring system.

Curve compensation

Most operators are not able to plant in perfectly square fields. Whether it is terraces or waterways, there are many field obstacles that make planting with curves impossible to avoid. When planters utilize drive shafts, they are not able to control each individual row-unit; as a result, planting on a curve presents an issue of maintaining 100 percent population. Since the inside rows are moving slower than the outside rows, the inside rows will be over populating while the outside rows are under populating.

With ExactEmerge and the curve compensation feature, each row will receive an individual signal based on the speed the row-unit is moving, maintaining the correct population across the length of the planter. Without curve compensation, there could be as much as a 24 percent drop in population accuracy, which is equivalent to 8,600 seeds per acre when planting at 36,000 seeds per acre. Curve compensation utilizes additional sensors on the planter and updated software to make precise changes to each row-unit to accurately maintain desired populations.

Easy Adjust row cleaners

Coulter

Coulter

Easy Adjust row cleaner

Easy Adjust row cleaner

Easy Adjust row cleaner and coulter combo provides a pneumatic row tillage solution that is controlled from the seat of the tractor.

Every decision to make an adjustment during spring planting reduces the acres planted per day and can increase or decrease profitability. An adjustment that can be overlooked is row cleaners due to planter size, difficulty to make the adjustment, varying conditions across fields and time.

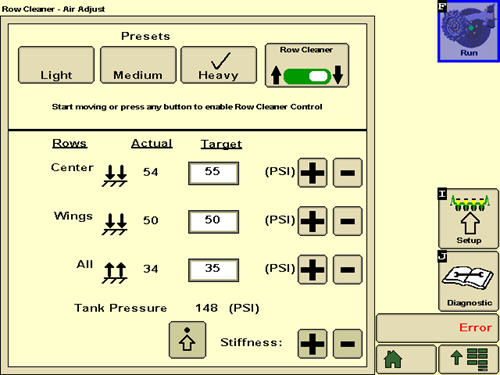

GreenStar™ 3 2630 Display view for Row Cleaners

GreenStar™ 3 2630 Display view for Row Cleaners

With the Easy Adjust row cleaners on ExactEmerge™ planters, operators now have a pneumatic solution to make on-the-go adjustments that is controlled directly from the seat of the cab. They can be raised from the cab as needed with the push of a button for wet areas, waterways, or end rows. The row cleaners are completely integrated into the John Deere GreenStar 2630 Display as well as the Gen 4 CommandCenter™ display with premium activation and do not require any additional monitors in the cab.

The Easy Adjust row cleaners have the capability to save three presets for varying ground engagement based on field conditions. The system is controlled in three sections, each wing as well as the center (frame or wheel) track rows. The pneumatic lines use air from the active pneumatic downforce compressor requiring no additional compressor to be installed on the planter. The Easy Adjust row cleaners utilize down and up force air bags. The adjustable air pressure setting for each bag allows the operator to set the ride of the row cleaner depending on the field conditions and the desired results. Making these on-the-go adjustments from tractor cab increases productivity and performance during planting.

The row cleaner only option utilizes parallel linkage to provide the floating action growers require in their fields. Parallel linkage allows for the unit to float up and down in the situation of hills or hard objects. The cleaner and coulter combo does not have parallel linkage, however, the row cleaners have floating rings installed to help provide the same benefits.

The row cleaners utilize the field-proven SharkTooth® design. Row cleaners play a major role in maximizing yield toward uniform emergence, reducing row-unit bounce and maintaining proper depth. The easy-adjust row cleaners provide growers with quick and stress-free solutions to customizing the planter in variable field conditions. Easy Adjust row cleaners are available on ExactEmerge and MaxEmerge 5e equipped planters. The Easy Adjust row cleaners are not integrated into RowCommand™ feature.

SharkTooth is a trademark of Yetter Manufacturing Incorporated.

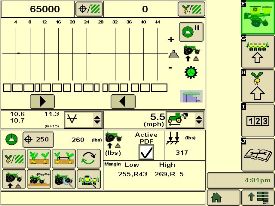

SeedStar™ 3 HP monitoring system

SeedStar 3 HP overview

SeedStar 3 HP shown on the GreenStar™ 3 (GS3) 2630 Display

SeedStar 3 HP shown on the GreenStar™ 3 (GS3) 2630 Display

Building upon the foundation of previous SeedStar monitoring, the SeedStar 3 HP monitoring system takes planter monitoring to the next level. When paired with the GS3 2630 Display, the SeedStar 3 HP monitoring system provides critical information about the planting process to the operator within the tractor cab. SeedStar 3 HP is compatible with the GS3 2630 and the Gen 4 4600 CommandCenter™ display.

Detailed planter performance information allows the operator to make adjustments needed for planter optimization. After all, with rising costs, it is imperative to make sure that every seed is planted accurately and precisely within the seed furrow for maximum yield potential.

The SeedStar 3 HP planting functions are fully integrated with the full spectrum of AMS applications such as John Deere Section Control for Planters, GreenStar (GS), AutoTrac™ assisted steering system, Apex™ software, John Deere Operations Center, JDLink™ telematics system, and others. Integrated planting technologies, for better asset utilization and ease of use, is just part of what SeedStar 3 HP provides.

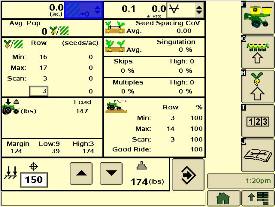

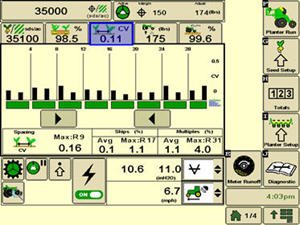

SeedStar 3 HP main run page

SeedStar 3 HP main run page

SeedStar 3 HP main run page

SeedStar 3 HP has an updated main run page layout. With the use of tabs toward the top of the screen it is much easier to navigate through readings such as population, singulation, spacing, downforce, and ride quality. If for some reason an issue arises with a row-unit, the tab will turn red indicating there is an issue. The tab can be pushed and lead to what is causing the issue. Inside each tab, there will be a bar graph detailing information specific to that tab. The picture shows what a population bar graph looks like. This layout improves functionality and overall ease of use while planting.

SeedStar 3 HP seed singulation monitoring

SeedStar 3 HP seed singulation planter run page

SeedStar 3 HP seed singulation planter run page

Understanding meter singulation performance on the planter is critical to minimizing the amount of seed multiples and skips. As a result, the SeedStar 3 HP monitoring system provides real-time information, from the redesigned seed sensors placed in each belt cartridge, about the overall seed singulation performance.

As seen in the screen shot image to the left, overall singulation performance is seen in the tab at the top of the screen. Seed skip and multiple sources of information are displayed below the bar graph of the run page. This provides the operator a better understanding of relative seed multiple and skip data on a row-unit basis within one easy glance at this run page.

Also, within the seed singulation planter run page, information about row units with the highest percentage of seed multiples and skips is provided in order to make necessary adjustments for better planter optimization.

SeedStar 3 HP row-unit down force planter run page

SeedStar 3 HP downforce planter run page

SeedStar 3 HP downforce planter run page

With changing field conditions, it is important to monitor down force to ensure consistent seed placement. Seeds placed too shallow or too deep can impact emergence and affect yield.

With the SeedStar 3 HP monitoring system, row-unit downforce information is measured by the down force sensor and sensor nodes and transmitted to the GS Display in the tractor cab. The row-unit down force information is displayed on the top portion of this run page with more row-unit down force information on the lower portion.

Active pneumatic down force takes SeedStar 3 HP even further by removing constant down force adjustments from the operator and actively controlling the downforce system to maintain a desired target margin. Just set the row-unit target margin value and the active pneumatic downforce system works automatically to make sure the planter maintains this value-achieving precise soil penetration, and consistent planting depth, without sidewall soil compaction. This frees the operator from constantly making manual downforce adjustments as conditions change.

SeedStar 3 HP ride quality and ground contact run page

SeedStar 3 HP ride quality and ground contact run page

SeedStar 3 HP ride quality and ground contact run page

The fifth tab from the left in SeedStar 3 HP is a shared tab between ground contact and ride quality. Operators may change between the two criteria based on their planter setups or personal preferences. Ground contact displays the percentage of time the row-units are engaging the ground, the load is measured via a sensor through the gauge wheels. Ground contact is recommended when using ExactEmerge row units to ensure the row-unit is maintaining proper depth at higher planting speeds.

SeedStar 3 HP seed spacing monitoring

SeedStar 3 HP seed spacing planter run page

SeedStar 3 HP seed spacing planter run page

Throughout the planting process, obtaining good seed spacing is critical towards achieving plant growing conditions for maximum yield potential.

Today, many items are adjusted on the planter prior to planting to optimize overall seed spacing performance. But after such adjustments are made, information about the actual seed spacing performance during planting was missing within the planter monitoring system. Now with SeedStar 3 HP, seed spacing information is transmitted live via the GS Display to show the operator exactly what is happening with the planter behind them.

The SeedStar 3 HP transmits seed spacing information onto the bar graph (shown to the left) for easy understanding of planter seed spacing performance. Also, information about seed skips and multiples are provided to help understand actual planter meter performance and other related system functions in order to make necessary adjustments if needed.

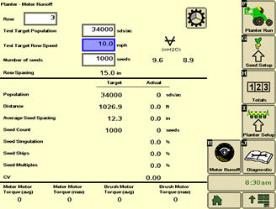

SeedStar 3 HP meter runoff page

SeedStar 3 HP runoff page

SeedStar 3 HP runoff page

On SeedStar 3 HP, the meter runoff page allows growers to test meters before going to the field. Growers can now test the meters without removing them and have confidence in your planter’s performance before going to the field. Many parameters are able to be viewed during this test such as: singulation, seed count, skips, multiples, coefficient of variation (cv), etc. This test assures that the meter is in healthy condition and ready to plant when conditions are appropriate.

Other SeedStar 3 HP monitoring features include:

- Capable of monitoring individual row-unit and overall planter performance in terms of seed spacing, singulation, and row-unit downforce

- On-screen indication of sensor node/down force sensor assemblies once configured within the monitor settings application

- Full-color display icons for easy recognition and overall aesthetics

- Pneumatic downforce system controls with the GS Display application

- The run page allows operator to view relative population levels of all rows on one screen

- Mapping of actual and target seed rates can be mapped in Apex

- Reprogrammable utilizing controller area network (CAN) via Service ADVISOR™ diagnostics system or Service ADVISOR Remote with JDLink™ subscription

- User-configurable high fertilizer pressure alarm. Allows the operator to be warned when fertilizer pressure reaches a specific level

- Automatic Fast Start for SeedStar 3 HP. This ensures that seeds will be place accurately when starting from a stop

- Automatic tractor speed source selection. When equipped with an 8000/9000 Series Tractor, the system selects the radar speed or allows for manual speed input selection

Components and operation

Planter main controller

Planter main controller

Row-unit controller (RUC) with two electric motors

Row-unit controller (RUC) with two electric motors

The SeedStar 3 HP monitoring system contains the following components in order to support the planting data transfer to the GS Displays:

- Planter main controller

- Sensor node(s)

- Downforce sensor assembly

- Electric power gen controller

- Electric power gen (EPG)

- Row-unit controller (RUC)

The row-unit controller processes the row-unit data from the sensor node assemblies located on the row-unit head casting. The processed information is then sent to the planter main controller to be integrated into the displayed information being sent to the GS Display.

Downforce sensor assemblies are found on row units with sensor nodes installed. The downforce sensor assembly is put together with the gauge wheel depth-adjustment handle and provides gauge wheel pressure information to the respective sensor node for data processing.

Depending on the planter size, different configurations of sensor nodes and downforce sensors are installed in support of the SeedStar 3 HP monitoring system.

SeedStar 3 HP is only available with the MaxEmerge 5e and ExactEmerge™ row-unit compatible planters.

MaxEmerge™ 5 row-unit

MaxEmerge 5 with 56-L (1.6-bu) hopper plus insecticide

MaxEmerge 5 with 56-L (1.6-bu) hopper plus insecticide

MaxEmerge 5 with mini hopper on CCS™ machines only

MaxEmerge 5 with mini hopper on CCS™ machines only

The MaxEmerge family of row-units have never seen a more versatile and efficient design until the MaxEmerge 5. The 5-family row-units improve productivity, increase uptime and lower the cost of ownership like never before.

The MaxEmerge 5 row-unit was designed for improved performance and serviceability.

Serviceability and changing crops has always been a focus of downtime and potential seed loss. MaxEmerge XP row-units (shown on the left) are designed with the meter and hopper as one component. The frame covers the meter so that it cannot be accessed. Cleanout of excess seed requires the operator to take the entire hopper off of the row-unit and to turn it upside down. The MaxEmerge 5 meter (shown on the right) is accessible without having to remove the box. The MaxEmerge 5 design allows large hoppers to be cleaned out the same as mini-hoppers, simply by opening the meter dome and catching the seed as it falls out. This improvement allows operators to change seed varieties easier and three times faster than it took them on the previous MaxEmerge XP units and provides more uptime during the tight planting window.

MaxEmerge™ 5 vacuum seed meter

MaxEmerge™ 5 vacuum seed meter

The vacuum meter system gently pulls and holds individual seeds to the holes of the seed disk for population control and spacing accuracy, equaling better crop stands and profit. Vacuum seed meters can plant a wide variety of crops and seed types by simply changing seed disks and adjusting vacuum level. Vacuum seed meters are available for planters with MaxEmerge 5 row-units.

Additional features of the vacuum seed meter include:

- One moving component (the seed metering disk) for minimum maintenance requirements

- Meter located at each row-unit for accurate seed delivery

- Good hopper seed flow characteristics for longer operating time per hopper fill

- Low airflow in meter so seed treatments are not removed

Pro-Series™ seed pool

Pro-Series™ seed pool

MaxEmerge 5 seed pool

MaxEmerge 5 seed pool

The MaxEmerge 5 meter shape has also been redesigned for better seed flow. The mini-hopper design allows the planter to successfully operate on side hills up to 14 degrees.

Vacuum meter hub and latching handle

MaxEmerge 5 vacuum meter with disk

MaxEmerge 5 vacuum meter with disk

Both the MaxEmerge 5 vacuum meters are equipped with a heavy-duty hub spring and disk latching handle. The spring ensures the seed disk stays properly positioned when operating flat-style seed disks and higher vacuum levels. Proper seed disk positioning means repeatable seed singulation, time after time. The disk-latching handle is designed for easy operation and effortless seed disk changeover. The hub is also machined to tight tolerances to further ensure alignment of metering components.

Operating characteristics of vacuum seed meter

Operating speed with seed tube technology

Operating speed with seed tube technology

The vacuum seed meter is capable of operating at faster planting speeds than mechanical meters. However, planting accuracy will be influenced by seedbed conditions and the operating characteristics of the seed meter. Rough seedbeds and fast planting speeds (above 8.9 km/h [5.5 mph]) typically deteriorate seed placement accuracies when using seed tube technology.

The chart illustrates the effect operating speed has on population when using the vacuum meter. The operating band (color area) illustrates how the vacuum meter performs in relation to the desired population (indicated by horizontal line). The width of the band is due to various sizes and shapes of seeds and planting rate variations.

When operating on slopes above 15 degrees, increased or decreased population may result. To minimize this effect, reduce speed and consider using a flat style seed disk with increased vacuum level.

Vacuum meter seed disks

The ProMAX 40 Flat Disk: The flat-disk planting solution field-proven to work since 1991

The design of the ProMAX 40 Flat Disk position allows seed to be released from the optimum position above the seed tube. The flush-face seed tube allows the seed to drop uninterrupted through the tube.

The ProMAX 40 Flat Disk utilizes flat holes and a higher vacuum level to ensure every hole is populated with a seed. A double eliminator gently removes multiple seeds at each hole for precise population control. A knockout wheel makes certain that each hole is clear of any debris after the seed is released from the disk.

Flat-style and cell seed disks shown

Flat-style and cell seed disks shown

The unique cell disk design allows planting a variety of seed sizes without any additional parts or individual meter adjustments. Another advantage of cell-type seed disks is the lower vacuum requirement compared to flat-style seed disks. Lower vacuum levels mean less hydraulic demand from the tractor. Most planting conditions call for a flat disk, if you are limited in hydraulic capacity, cell disks are recommended.

Double eliminator

For difficult to singulate seeds, a flat seed disk and double eliminator is a viable alternative to traditional cell-type seed disks. By design, a flat seed disk requires higher levels of vacuum than a cell-type disk because there is no pocket or cell to hold the seed. The higher vacuum level will pull more than one seed to the holes in the seed disk. The double eliminator is set to cover a portion of the hole in the seed disk and is the mechanism to knock multiple seeds away as the disk rotates.

Double eliminators are required with flat-type seed disks only and should not be used with cell-type seed disks. The knockout wheel is also recommended in conjunction with the double eliminator and flat seed disk to ensure seed is ejected from the disk.

Flat and celled type seed metering disks are available to allow planting a wide variety of seed types.

- Corn (field, popcorn or sweet corn)

- Soybeans

- Cotton

- Sorghum

- Sugar beets

- Sunflowers

- Edible beans/peas

- Peanuts

- Melons, squash, cucumbers

Mini-hopper row-units, which are used only with the Central Commodity System (CCS™) are compatible only with crops that the CCS is approved to plant.

- Corn

- Popcorn

- Sweet corn

- Soybeans

- Sunflowers

- Sorghum

- Cotton

NOTE: Due to small seed size and low planting populations, sugar beets can be planted with mini-hopper style meters by adding hopper extensions and not using the CCS tank. These hopper extensions can also be used for planting test plots.

Hopper shutoff

Hopper shutoff

Also, to help with meter access of 56-L and 106-L (1.6-bu and 3-bu) hoppers the hopper shutoff feature was added. With the shutoff engaged, the meter cover can be opened without first having to remove all of the seeds from the hopper. Lever down, the seed flow is on, lever horizontal and the seed flow is off.

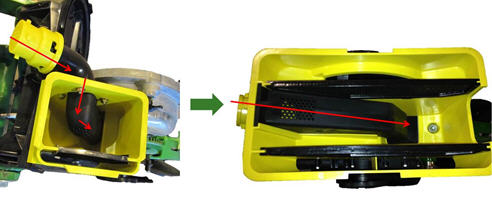

MaxEmerge 5 mini-hopper

MaxEmerge 5 mini-hopper

There are significant changes to the MaxEmerge 5 Mini-Hopper. One update is the straight feed from the Central Commodity System (CCS™) hose to the mini-hopper to ensure a continuous free flow of seeds. This design change reduces the potential for plugging issues with larger seed size and the use of seed treatments. By drawing air from the CCS tank the vacuum source is now cleaner, preventing meter debris buildup.

Ductile iron-cast shank

Ductile iron-cast shank

Ductile iron casting is a unique high-tech process that produces a single-piece row-unit shank this enables alignment from the seed trench to the closing wheel.

The row-unit head is also designed using the ductile iron-casting process. The row-unit head provides the mating joints between the row-unit parallel arms and the row-unit shank. It is also the upper attaching point for the seed meter and seed hopper.

Ductile iron casting of the row-unit shank and head assembly provides a row-unit that is 25 percent stronger than other competitive welded row-units.

One of the trademark capabilities of John Deere planters has always been the ability of the Tru-Vee™ openers to provide an ideal seed furrow.

The thickness of the Tru-Vee opener blade is 3.5 mm (0.14 in.) this blade thickness will provide extended wear life.

The MaxEmerge 5 row-unit also provides better Tru-Vee opener bearings for longer life. The double-row ball bearing provides up to three times the wear life as the single-row bearing.

Depth adjustment T-handle

Depth adjustment T-handle

John Deere planters provide consistent seed depth control in all field conditions. Depth control is a function of the Tru-Vee openers, the downforce system, and the gauge wheel assembly.

The gauge wheel itself is made of durable nylon composition with a concave profile. This profile gently firms the sides of the seed furrow, ensuring a well-defined trench. The shape reduces rocks and residue being picked up and thrown onto the drive chains and row-units, and helps to prevent rooster tailing of soil.

The bolt-through design utilizes an open bearing in the gauge wheel that allows an attaching bolt to pass through the wheel to the threaded hole in the gauge wheel arm. This simple bolt-through design provides for a positive attachment of the gauge wheel to the gauge wheel arm and allows quick removal of the gauge wheel for service.

Adjustability of the row-unit is critical to good performance. More available downforce options than any row unit in the industry

- Adjustable heavy-duty downforce, four settings, 0 kg (0 lb), 57 kg (125 lb), 113 kg (250 lb), and 181 kg (400 lb) of downforce

- Pneumatic downforce, infinitely variable from 0 to 181 kg (0 to 400 lb) of downforce

- Active pneumatic downforce adjusts automatically for changing ground conditions from 0 to 181 kg (0 to 400 lb) of downforce

Rubber tire closing system

Rubber tire closing system

Cast wheel closing system

Cast wheel closing system

Rubber tire closing systems are used for most conventional, minimum-till, and no-till planting conditions. The spacing between the wheels is adjustable so the closing system can meet the needs of those who want to plant small seeds at shallow depths.

The wheels can also be staggered fore and aft to enhance residue flow. Four levels of spring force are available and are easily set with the integrated T-handle adjustment. A lower force spring can be obtained from parts, if a lower amount of force is required.

Additional closing wheel options include:

- Cast closing wheels, for tough-to-close conditions

- Disk closing, for shallow planting depths

- Closing wheel frame less wheels, for growers desiring to use aftermarket closing wheels

Downforce system options

Heavy-duty adjustable downforce springs

Heavy-duty adjustable downforce spring

Heavy-duty adjustable downforce spring

Planter row-unit downforce is an important factor to ensure consistent and proper depth control. The heavy-duty adjustable downforce feature provides up to 400 lb of downforce. There are four settings available to allow the user to choose the amount of downforce required for the condition: 0 lb, 125 lb, 250 lb, and 400 lb.

Compatibility: 1705, 1715, 1725, 1735, 1755, 1765, 1765NT, 1775 Flex, and 1785

Standard pneumatic downforce system

Pneumatic downforce provides convenient, simple adjustment of downforce for the whole planter from one location. The amount of downforce applied is infinitely adjustable from 0 to 181.80 kg (0 to 400 lb). Pneumatic downforce provides more consistent downforce throughout the range of row-unit travel than mechanical spring downforce systems.

Features include:

- 9.5-mm (3/8-in.) air delivery line instead of the 6.4-mm (1/4-in.) line used on model year 2010 and older planters.

- Air compressor assembly increased duty cycle. With this compressor, it provides a 47 percent increase in maximum air flow delivery compared to the prior air compressor.

- Pneumatic air bags with 9.5-mm (3/8-in.) air line inlets that have greater durability.

Pneumatic downforce spring

Pneumatic downforce spring

Each row-unit has a single rubber air bag located between the parallel arms. The air bags are hooked in parallel so that air can be added or released from all rows at once from one location.

The individual pneumatic downforce air bag assemblies, air compressor units, and 9.5-mm (3/8-in.) delivery lines are also available as an attachment for field conversion.

Pneumatic downforce compressor and gauge

Pneumatic downforce compressor and gauge

An improved compressor is used to charge the pneumatic system. This compressor can be located on the planter frame or in the tractor cab if desired. A gauge at the compressor indicates the amount of downforce being applied.

From the factory, integral planter models with pneumatic downforce will have an improved air compressor assembly with an in-cab mounting bracket, except the 1725 16-row and 1725 Central Commodity System (CCS™ ) twin row planters will have the air compressor assembly mounted on the planter frame. For drawn planter models, the 1755, 1765, 1765NT, 1775 Front-Fold, and 1785 Drawn Planters will have the air compressor assembly installed either on the outer hitch or wing frame members when the pneumatic downforce system is installed.

Base equipment on: 1705, 1715, 1725, 1735, 1755, 1765, 1765NT, 1775 and 1785.

Integrated pneumatic downforce system

The functional features of the integrated system are the same as the standard pneumatic system, explained above, with the addition of control through the GreenStar™ display.

System control with GreenStar™ (GS) display

Pneumatic downforce control in GS2 display

Pneumatic downforce control in GS2 display

Air compressor mounted on 1775NT outer hitch

Air compressor mounted on 1775NT outer hitch

On 1725 16-row, 1725 Central Commodity System (CCS™) TR, 1775NT, 1775NT CCS, 1795, DR, and DB Series Planter models, the air compressor will be mounted on the outer hitch or frame assembly. Since the air compressor assembly is mounted on the outer hitch (as noted in the picture above) or frame, adjustments for row-unit downforce and related system pressures will be made electronically with the GS Display.

When adjusting the amount of row-unit downforce using the GS Display, the operator will select the amount of downforce (lb) to be applied across the planter. Depending on the soil conditions at hand, the operator might need to adjust the relative amount of row-unit downforce being applied during the planting operation. The integrated pneumatic downforce controls within the GS Display will only allow for set-point operation and not automatic control as the planter is operating in different soil conditions. The pneumatic downforce system does not have the capability to automatically adjust downforce.

On-board air storage

Onboard air storage installed on 1775NT 24R30

Onboard air storage installed on 1775NT 24R30

The 1725 16-row, 1725 CCS TR, 1775NT, 1775NT CCS, 1795, DR, and DB Series planters will have onboard air storage to increase the overall response time when making a row-unit down force adjustment from the GS Display. The onboard air storage is comprised of a 19-L (5-gal.) storage tank with valve assembly.

Base equipment on: 1725 CCS, 1725 16-row, 1725T, 1775NT, 1775NT CCS, 1795, DR, and DB Series Planters with MaxEmerge™ 5 row units. MaxEmerge 5e and ExactEmerge™ equipped planters come with active pneumatic downforce in base.

Active pneumatic downforce

Active downforce compressor assembly

Active downforce compressor assembly

Hydraulic motor

Hydraulic motor

A hydraulically driven compressor works with the SeedStar™ 3 HP system and SeedStar XP system to automate downforce control. Just set the row-unit target margin value and the active pneumatic downforce system works automatically. The system will make sure the planter maintains this value, achieving precise soil penetration, and consistent planting depth, without sidewall soil compaction. From the factory the system is set at 100 lb target downforce margin, but may be modified for varying field conditions. This frees the operator from constantly making manual downforce adjustments as conditions change.

This system offers a split rank control feature for 1795 and DB Split-Row Planters. On split row planters active downforce will control the front and rear rows independently. This compensates for differing downforce requirements between the ranks that can be caused from things like different tillage or insecticide attachments and will help maintain an accurate planting depth and consistent margin across all the rows.

Active pneumatic downforce is available as factory installed or as an attachment for field conversion.

SeedStar XP row-unit downforce planter run page

SeedStar XP downforce planter run page

SeedStar XP downforce planter run page

Active downforce control is integrated into SeedStar XP and SeedStar 3HP monitoring systems.

Margin is the amount of weight riding on the depth gauge wheels that ensures desired firming of the seedbed as set by the operator.

Once a target margin has been defined, enter the value into SeedStar XP or SeedStar 3HP and let active downforce do the rest. The system will actively adjust the air pressure in the air bags to maintain a constant margin across the planter. The changes in air pressure will change the amount of downforce placed on the row unit compensating and reacting for varying conditions through the field whether it is different tillage practices, soil types, or moisture.

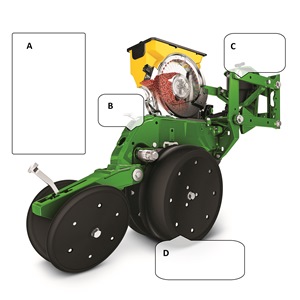

Down force and margin example

Down force and margin example

A) Margin – Amount of additional down force applied to a row unit above and beyond what is required for penetration to achieve planting depth. This additional weight will ride on the depth gauge wheels. 120 + 80 = (200 – 150) = 23 kg (50 lb) of margin

B) Weight of row-unit - 54 kg (120 lbs)

C) Downforce – Force that is applied to the row-unit by the air bag circuit - 36 kg (80 lb)

D) Resistance from soil - 68 kg (150 lb)

Hydraulically driven compressor

Hydraulic motor

Hydraulic motor

Pneumatic valve

Pneumatic valve

The hydraulically driven air compressor can deliver up to eight times the air flow allowing for more and faster downforce changes to be made. This more robust design features a 38-L (10-gal.) storage tank across all models with active downforce.

At approximately 4 gpm, hydraulic demands are low and ties into the machine’s lift and Central Commodity System (CCS™) hydraulic circuit so it does not require any additional selective control valves (SCVs). The SeedStar XP and SeedStar 3HP monitoring systems work with the compressor and valve assembly to regulate air to downforce springs enabling the active control.

Another feature of John Deere active downforce is the ability for the pneumatic valve to independently control split rank machines. This system senses the downforce needs from the front and rear ranks separately and independently adjust air pressures with the dual rank pneumatic valve when equipped. Active pneumatic downforce requires SeedStar XP or SeedStar 3HP to enable active control.

Base equipment on: All MaxEmerge™ 5e and ExactEmerge™ equipped planter models.

Individual row hydraulic downforce (IRHD)

IRHD has been specifically designed to meet the needs of producers that are looking to adjust to the toughest field conditions and provide maximum yield potential from field to field, season after season. IRHD works as a closed-loop downforce system that reacts quickly on an individual row basis to changing soil conditions supporting increased ground contact, which can lead to improved seed depth consistency. When setting planter downforce margin the system will apply the needed downforce by row to maintain ground contact. From the factory the margin will be set at 100 lb, changes may be required based on varying field conditions.

The system allows growers to maintain gauge wheel ground contact leading to desired seed depth placement. IRHD can adjust five times per second and make adjustments of 45.4 kg (100 lb) in less than a second. The system has a total range of applied downforce from 50 lb to 450 lb and utilizes the power beyond circuit on the tractor. IRHD is 58 percent faster than active pneumatic downforce solution. Fast reaction and increased ground contact can lead to improved emergence. With uniform emergence some studies have shown a yield impact from 5% to 9%.

Optional equipment on: 1775NT, 1795 and DB models with MaxEmerge™ 5e and ExactEmerge™ row units.

DB60 24R30 frame

Three-section, front-fold toolbar

DB planter

DB planter

The DB60 24R30 Central Commodity System (CCS™) with Pro-Series XP™ row-unit planters feature the Bauer Built Mfg. frame that offers increased strength through the use of 7-in. x 7-in. steel. Not only rugged, both of these well-designed frames offer a clean look, with neatly routed hoses and cables for easy servicing.

The DB60 Planter frame has superior frame flexibility for even-depth planting when working rolling ground. The three-section frames allow each wing to flex 15 degrees up and down relative to the planter's center section.

The DB60 24R30 features 6 row-units on the center frame section and 9 row-units on each wing.

Transport

DB in transport

DB in transport

The DB60 24R30 Planter equipped with Pro-Series XP row-units folds to a transport width of 15 ft and a length of 41 ft.

The combination of narrower transport widths, low center of gravity, and more ground clearance make the DB60 a very stable planter in transport.

Frame tires

DB main frame tires

DB main frame tires

DB optional mainframe tires

DB optional mainframe tires

Four large 16.5 x 16.1 main frame tires and four 31-13.5x15 wing tires keep the DB60 floating on top of the ground, while wheel spacing improves residue flow. Each wing also utilizes a walking tandem for even planting and excellent float across unlevel fields. The DB60 can be equipped with larger 445/50R22.5 mainframe tires as an option.

RowCommand™ individual-row control system

RowCommand controls seed output

RowCommand on a MaxEmerge™ 5 row-unit

RowCommand on a MaxEmerge™ 5 row-unit

RowCommand on a chain drive MaxEmerge 5 row-unit

RowCommand on a chain drive MaxEmerge 5 row-unit

Controlling input costs and improving productivity are key producer requirements today. RowCommand is an effective, integrated John Deere solution designed to meet these intensifying needs. The RowCommand system manages seed output, reduces yield drag, and improves harvest capabilities on all Pro-Shaft™ driven row-units, and chain-driven MaxEmerge 5.

NOTE: Chain-drive RowCommand is only compatible with planters equipped with pneumatic downforce systems. On planters equipped with the heavy-duty downforce springs, potential chain interference may result and is not recommended.

NOTE: Chain-drive RowCommand requires some modification to brackets in order to function with corn finger pickup meters.

NOTE: Pro-Shaft drive RowCommand is compatible on MaxEmerge 5 row-units with vacuum and corn finger pickup meters. For mini hopper row-units, RowCommand is compatible on vacuum meters only and is not compatible on corn finger pickup meters. Pro-Series XP row-units with corn finger pickup meters are not compatible with RowCommand.

RowCommand controls seed output by incorporating individual, low amperage clutches inside the Pro-Shaft and chain-driven gearboxes. Clutches are completely enclosed within the gearbox housing to protect them from the elements and harsh operating conditions.

When power is supplied, either manually or through John Deere Section Control software, clutches disengage the seed meters and seed flow stops. Controlling seed output at individual rows reduces overplanting in point rows and maximizes seed placement when entering/exiting headlands.

Components and operation

EPMs shown on a 1775 NT Planter

EPMs shown on a 1775 NT Planter

RowCommand clutch on MaxEmerge 5 with 3-bu hopper

RowCommand clutch on MaxEmerge 5 with 3-bu hopper

RowCommand is a simple and efficient solution to control individual row planting. This system does not utilize air to operate; therefore, no compressor, air lines, or valve modules are required.

RowCommand utilizes low-voltage controller area network (CAN) messaging to signal power to the desired clutches to stop planting or eliminates power to resume planting.

This means very little power is used in normal planting conditions, and in the event a clutch fails electrically, the meter will continue to plant.

The RowCommand system requires the following five basic components to operate:

-

Electric clutches

-

Electronic power modules (EPMs)

-

SeedStar™ 2 monitoring (wedge box/controller)

-

GreenStar™ (GS) display

-

Planter wiring harnesses

Clutches are protected within the sealed Pro-Shaft and chain-driven gearboxes for years of trouble-free operation and simple installation or removal. RowCommand has true individual-row control of up to 16 clutches or sections for planters larger than 16 rows.

Unique to RowCommand, the 16 available control sections can be configured based on operator preferences. For example, on a 1775 NT 24-Row Planter, every two rows can be paired together for a total of 12 control sections, or control the outermost eight rows individually and the remaining inner rows paired together for 16 control sections.

While SeedStar with RowCommand has 16 control sections, a minimum of 152-cm (60-in.) wide sections are recommended for optimum Swath Control Pro™ solution capabilities. As with other Swath Control Pro products, a SF 2 signal is the minimum level of accuracy recommend for operation.

Pro-Shaft drive RowCommand planters

RowCommand is available as a factory-installed option or as an attachment for field conversion attachments for the following Pro-Shaft drive planter models (see chart below).

| Planter model | Row configuration |

| 1725 | 12-row narrow, 12-row wide, and 16-row narrow |

| 1725 CCS™ | 16-row narrow |

| 1765 | 12-row narrow |

| 1775 | 12-row narrow |

| 1775NT | 12 row, 16 row, and 24-row narrow |

| 1775NT CCS | 12 row, 16 row, and 24-row narrow |

| 1795 | 12/23 row, 12/24 row, 16/31 row, and 16/32 row |

| 1795 | 24 row, 50 cm (20 in.) |

| DB 44 | 24 row, 56 cm (22 in.) |

| DB 58 | 32 row, 56 cm (22 in.) |

| DB 60 | 36 row, 50 cm (20 in.) or 47 row, 38 cm (15 in.) |

| DB 66 | 36 row, 56 cm (22 in.) |

| DB 80 | 32 row, 76 cm (30 in.) or 48 row, 50 cm (20 in.) |

| DB 88 | 48 row, 56 cm (22 in.) |

| DB 90 | 36 row, 76 cm (30 in.) |

| DB 120 | 48 row, 76 cm (30 in.) |

DR (Deere/Orthman™ planter) 16R40 |

16 row, 102 cm (40 in.) |

| DR (Deere/Orthman) 18R38 | 18 row, 97 cm (38 in.) |

Chain drive RowCommand planters

In terms of planter compatibility, RowCommand for chain drive is designed for the following planter model configurations equipped with pneumatic downforce systems.

| Planter model | Row configuration |

| 1725 | 12-row narrow, 12-row wide, and 16-row narrow |

| 1765 | 12-row narrow |

| 1775 | 12-row narrow |

| 1775NT | 12 row, 16 row, and 24-row narrow |

| 1775NT CCS | 12 row, 16 row, and 24-row narrow |

| DB 44 | 24 row, 56 cm (22 in.) |

Chain drive RowCommand and heavy-duty downforce

Chain interference with heavy-duty downforce

Chain interference with heavy-duty downforce

As seen in the picture, chain interference may result when operating chain-drive RowCommand on planters equipped with short and long parallel arms and heavy-duty downforce springs.

NOTE: Chain-drive RowCommand is only compatible with planters equipped with pneumatic downforce systems. On planters equipped with the heavy-duty downforce springs, potential chain interference may result and is not recommended.

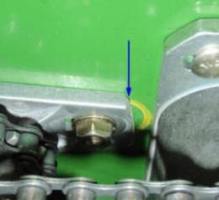

Chain-drive RowCommand with corn finger pickup meters

Bracket material removal

Bracket material removal

Due to the design characteristics of the chain drive RowCommand clutch, some modification to the corn finger pickup meter drive bracket is required. As seen in the picture to the left, some material needs to be removed from the front of the meter drive bracket in order for the chain-drive RowCommand clutch to have sufficient space for installation.

NOTE: Chain drive RowCommand requires some modification to brackets in order to function with corn finger pickup meters.

RowCommand ordering information

To add RowCommand to a model year 2009 and newer planter model listed above is simple. Pro-Shaft drive attachments for field conversion and chain drive attachments for field conversion are available by planter model to add the appropriate number of clutches, EPMs, brackets, hardware and row-unit harnesses. For complete installation and part detail for the RowCommand conversion, please use the RowCommand compatibility tool per specific planter model.

RowCommand is compatible and available for model year 2003 (serial number 700101) to 2008 (725101) planter models listed above. In addition to the attachment for field conversion attachment, a planter mainframe harness, SeedStar 2 controller (wedge box), and additional CAN harnesses are needed.

Integrated Swath Control Pro

Coupling RowCommand with Swath Control Pro provides the ultimate in precision planting and productivity. One company, one integrated solution are what we offer by incorporating Swath Control Pro capabilities within the SeedStar 2 wedge box (controller). Unlike previous systems, no rate controller, additional harnessing, or components are required to achieve automated individual-row control.

SeedStar 2 monitoring, RowCommand, and Swath Control Pro activation from John Deere Precision Ag Technologies are all that is needed when ordering.

System requirements

RowCommand is a simple and efficient means to control individual row planting through the use of low-voltage electric clutches. When activated, each clutch consumes no more than 0.5 amps. By design, power is only supplied to the clutch when a signal is received to stop planting. In a normal planting condition, no power is supplied and the clutch is de-energized.

Power for the RowCommand system is provided from the 9-pin ISO implement connector. All late-model 8X00 and 9X00 Series John Deere Tractors equipped with the 9-pin ISO implement connector are capable of supplying ample power for system operation.

Along with ample system power, a GreenStar display and SeedStar monitoring are required for operation and control interface. The GreenStar display is where system setup, control settings, and manual control functions are performed.

Provide added versatility and productivity with Central Commodity System (CCS™) Refuge Plus™ planter configuration

CCS Refuge Plus option shown on 1775NT

CCS Refuge Plus option shown on 1775NT

1775NT, 1795, and DB models with CCS can be equipped with the Refuge Plus option.

The third tank on the Refuge Plus system provides increased versatility and productivity to the planting operation by allowing the grower to plant two different varieties simultaneously. The Refuge Plus tank has manifold nozzles, or outlets, to supply seed to eight different row-units.

Refuge Plus is ideal for the corn grower planting Bt corn or seed corn. Refuge Plus is the solution for refuge management compliance issues associated with Bt corn production. The 880-L (25-bu) capacity of the third tank makes planting the required 20 percent refuge of non-Bt corn easier while maintaining high productivity levels of the central-fill CCS.

For example, the Bt corn planted on 80 percent of the field goes into the larger CCS tanks. The required 20 percent refuge, non-Bt corn, goes into the third Refuge Plus tank with the seed hoses routed to the desired rows.

Central fill with CCS is now easier for the seed-corn grower as well. The seed-corn grower can plant both male and female seed in the desired pattern simply by placing the male seed in the Refuge Plus tank, the female seed in the CCS tanks, and routing the seed delivery hoses to the desired row units.

Redirecting seed delivery

Seed delivery hose connection and yellow plug

Seed delivery hose connection and yellow plug

Redirecting seed delivery from the CCS tanks to the Refuge Plus tank is a snap with quick- disconnect couplers. By simply disconnecting the desired CCS delivery hoses from beneath the CCS tank, capping those hoses and reconnecting the delivery lines to the Refuge Plus tank the seed delivery source is changed.

Due to the additional weight Refuge Plus places on the planter frame, liquid fertilizer tanks are not compatible. Updated liquid insecticide tank codes have been established for Refuge Plus Planters.

Seed variable rate drive (VRD) with half- or three-width disconnect

VRD shown on a 1775NT

VRD shown on a 1775NT

The seed variable-rate drive provides the ultimate planting productivity by utilizing one, two or three hydraulic motors (varies by model) to turn the seeding drive shaft. Hydraulic control of the seeding drive allows for on-the-go seeding rate changes right from the display mounted inside the tractor cab.

Combine this seeding flexibility with the map-based planting option, and seeding rates adjust automatically based on a prescription map.

Single- or dual-motor systems for variable-rate drives are available for all John Deere planters except the 1785 Rigid Frame. Dual- or three-motor drive systems are commonly used on larger (12-row and more) planters and offer the capability of half-width or three-section drive disconnect.

The VRD is available as a factory-installed option for all applicable planter models. Single- or dual-motor systems are available as field-installed attachments for most planter models; however, a three-motor VRD field-installed attachment is not available.

The seed VRD requires the SeedStar™ monitor and a radar input signal. Either tractor or planter radar may be used. Planter radar is ordered separately.

VRD offers the following advantages over common, contact-tire drive systems:

-

Almost instantaneous rate changes; there is no ramp up or ramp down of system as in some competitive systems

- Permits the operator to match seed population based on different soil types or irrigation practices

- John Deere design that provides added operator safety by eliminating any possible drive creep found in some competitive variable rate drive systems

Half-width drive disconnect

The half-width drive disconnect feature is excellent for the producer concerned with controlling seed costs. This feature helps the operator place seed in the desired area and limit the amount of costly overlapped planting.

The half-width drive disconnect allows the operator to turn off half of the planter at a time for planting end rows, point rows, etc. Variable-rate-equipped planters require two drive motors to utilize the half-width disconnect feature.

Half-width drive disconnect within frame control

Half-width drive disconnect within frame control

With a 1765, 1765NT, and 1775 12-Row Planter, a single switch box is required for planters that are ordered with variable rate drive and half-width disconnect.

For the 1775NT, 1775NT Central Commodity System (CCS™), and 1795 Front-Folding Planters, the half-width drive disconnect switch is contained within the frame control box, conveniently located in the tractor cab. The function easily shuts off the drive for the left or right half of the planter row-unit seed meters.

Three-width drive disconnect

Three-width drive disconnect control

Three-width drive disconnect control

Three-width drive disconnect is an option on 1725 12-Row Planters and is base equipment on the 1725 16Row30 Planter. This feature is activated by three individual console mounted switches (control box), conveniently located in the tractor cab. The function easily shuts off the planter row-unit seed meters by one-, two-, or three-drive segments independently.

Central Commodity System (CCS™) seed delivery system

CCS

CCS

CCS seed delivery adds productivity through increased seed capacity, bulk fill capability, and easy, thorough cleanout.

The two tanks have a combined capacity of 2470 L (70 bu) on 9-m (30-ft) planters and 3520 L (100 bu) on 12-m (40-ft) and larger planters. CCS tanks are manufactured using a rotomolded, polyethylene design to ensure maximum durability. The translucent tanks allow easily viewing the amount of seed in the tanks. The tanks are separated by 55 cm (21.5 in.) for enhanced rear visibility during transport and backing.

The following crops can be planted with CCS: corn, sweet corn, popcorn, cotton, sunflowers, soybeans and sorghum (milo). Currently ExactEmerge™ planter is only compatible with corn, soybeans, popcorn, and cotton.

Filling the tanks is convenient due to a central filling location. The staircase and railing provide access to the filling platform between the tanks. If filling the tanks with an auger, minimum recommendations are a 15-cm (6-in.) diameter, 4.3-m (14-ft) auger. Each tank has an adjustable, bin-level sensor to alert the operator when it is time to fill.

A standard fill light package is available on machines equipped with CCS. This feature includes two lights conveniently mounted on the railings of the machine. The lights are turned on and off with their own switch located at the bottom of the staircase.

If the seed-carrying vehicle requires hydraulic power to run the unloading system, the auxiliary hydraulic coupler option is available. These couplers are located at the bottom of the staircase and can be coupled under pressure. The system has a separate system filter that ensures your planter hydraulic system remains free of contaminates.

Seed delivery process

CCS is about reducing the time spent filling the planter with seed while maximizing the time spent planting. CCS for planters is a form of seed handling and delivery. The row-units perform the final task of seed metering and placement.

The CCS seed delivery process relies on a hydraulically-driven fan to move seed from the CCS tanks to the row-units. This fan is plumbed in to the planter's raise/lower circuit, so only one selective control valve (SCV) is needed for both functions. When the planter is lowered, lift cylinders bottom out and hydraulic flow is diverted to the seed delivery fan. A flow control valve and gauge, located near the tank, allows for the proper tank pressure setting based on seed type.

Air from the fan pressurizes the CCS tanks and delivers seed to the seed hoppers. Airflow enters the seed tanks through a nozzle in the manifold which pressurizes the tank. The air then picks up seed and moves out the other end of the nozzle into seed delivery hoses. These hoses route the seed toward the hopper. A small amount of seed is traveling in the delivery hoses only when needed.

The hopper fills with seed until the delivery hose (discharge elbow) is covered. Once the opening is restricted, seed flow through the hose stops. Air flowing to the row unit travels into the hopper and is the source of air for the vacuum system. This provides a much cleaner air source than previous meter designs. As the seed is picked up by the meter and planted, the seed pool shrinks until the end of the delivery hose is uncovered. At that time, the airflow and seed delivery resume and the seed pool in the hopper is replenished.

CCS seed clean-out

Seed cleanout could not be much easier with a CCS Planter. When finished planting, any remaining seed can simply be removed via access doors at the bottom of the CCS tank.

Because seed is only traveling through the CCS delivery hoses when required by the meter, there is not much left to clean.

Next, CCS seed delivery hoses are then purged with air from the CCS fan and the excess seed is pushed to the individual meters.

The vacuum meter door is opened and seed is removed with the supplied catch pan.

Small seed CCS components

Manifold nozzle and nozzle with cover installed

Manifold nozzle and nozzle with cover installed

Straight-seed inlet installed in mini hopper

Straight-seed inlet installed in mini hopper

CCS seed delivery system increases planting productivity across the seven approved crops listed above. While highly effective delivering seed from the CCS tanks to the vacuum meters, small or light seeds (sorghum and small cotton) will require two additional components to aid in proper seed delivery.

Manifold nozzle covers (clips) should be installed to ensure seed is adequately picked up into the air stream for delivery to the row-unit. Mini-hopper discharge elbows should also be changed from the standard elbow (holes) to the small seed elbow (slotted openings) when planting sorghum (milo) and small cotton.

Row cleaner options to meet residue management needs

As crop yields have increased over the years, so has the amount of residue left in the field after harvest. At the same time tillage practices have changed, including different tillage operations which maintain large amounts of surface residue, and even no till practices. Row cleaners are an essential tool in managing this increased amount of residue.

John Deere seeding group offers a variety of row cleaner options to meet the needs of a producer's operation. Compatibility varies by model, row spacing, and other planter equipment.

Screw-adjust unit-mounted row cleaner

Screw-adjust unit-mounted row cleaner

Screw-adjust unit-mounted row cleaner

The screw-adjust unit-mounted row cleaner is mounted directly to the face plate of the row-unit, placing the ground engaging components just in front of the row-unit opener blades and depth gauge wheels. This close proximity allows the gauge wheels to control the depth of the row cleaner as well as the row-unit. This compact design also allows greater compatibility with fertilizer openers and other planter attachments.

SharkTooth® wheels are standard equipment on the unit-mounted row cleaner. The swept-tooth design of the wheel provides a clear path for the row-unit openers while resisting residue buildup on the wheel. The screw adjustment knob is accessible through the top of the parallel arms, providing convenient access for adjustments. The row cleaner can be adjusted in 1.6-mm (1/16-in.) increments, providing plenty of flexibility to meet the needs of changing conditions.

Floating row cleaner with unit-mounted coulter

Floating row cleaner with unit-mounted coulter

Floating row cleaner with unit-mounted coulter

The floating row cleaner allows a row cleaner to be used in conjunction with a unit-mounted coulter. This combination is often desired in heavy residue loads and tough reduced tillage planting conditions. The row cleaner provides a clear path for the row-unit, while the unit-mounted coulter helps penetrate tough soil conditions.