Overview

- Best-in-class power with 6.7L Cummins diesel engine

- Improved performance in difficult conditions with optional all-wheel-steering and traction control

- Smooth, consistent ride with air bag suspension system

- Excellent visibility and operator comfort with application designed cab

Features

Features

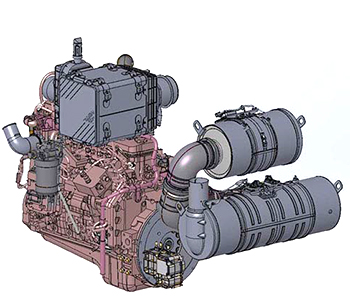

Hagie™ D400 Series engines

6.7-L (408.9-cu in.) Cummins® QSB engine

Final Tier 4 (FT4) diesel engine

Final Tier 4 (FT4) diesel engine

The Hagie D400 is powered by a 6.7-L (408.9-cu in.) Cummins QSB emissions-compliant Final Tier 4 (FT4) diesel engine rated at 145- kW (195-hp). This 6.7-L (408.9-cu in.) engine is electronic with an air-to-air cooler and turbocharger.

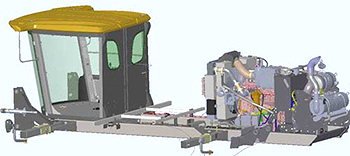

Engine location

Engine location (FT4 engine shown)

Engine location (FT4 engine shown)

The rear-mounted engine keeps constant weight to offset the front attachment and leaves space in the center of machine for the varying weight of the fuel tank. This allows for better coolant airflow and reduction of cab noise.

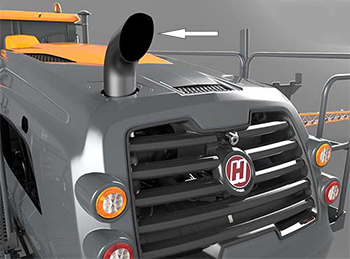

Engine exhaust

Engine exhaust stack

Engine exhaust stack

The engine exhaust is located at the rear of the machine. This helps to reduce interior cab noise and vibration.

Cummins is a trademark of Cummins, Inc. Hagie is a trademark of Hagie Manufacturing Company, LLC and similar to John Deere branded equipment, Deere will also support Hagie equipment.

D400 cab and controls overview

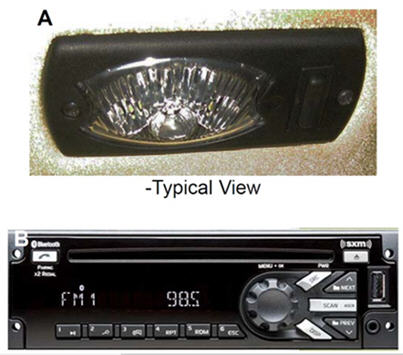

Overhead monitors and controls

| Location (image) | Component | Description/notes |

| A | Courtesy/interior work light | The courtesy light comes on automatically when the cab door is opened. The interior work light is activated by manually pressing the interior work light switch (located on the light housing). |

| B | Stereo (if equipped) | The stereo features an AM/FM tuner, weatherband broadcasting, CD player, MP3 player, USB/ iPod® controls, and Bluetooth® wireless system (if equipped). |

| C | Climate controls | The climate controls allow the operator to set and maintain desired cab temperature. Vents are placed throughout the cab to keep air circulating and to maintain clear windows throughout the cab. |

| D | Machine display | The machine display is the central control center of the machine. It controls many of the machine’s electronically driven functions (i.e., machine drive, all-wheel steer [AWS], attachment operation, tread adjustment, detasseling systems, lights, diagnostics, etc.). |

| E | Machine gauges | The machine gauge panel on the A-post is conveniently located for viewing engine rpm, fuel level, engine coolant temperature, and engine aftertreatment level (if equipped). |

Side console

| Location (image) | Component | Description/notes |

| A | Emergency stop (e-stop) switch | The e-stop switch provides a quick method for stopping the engine in an emergency situation. |

| B | 4-1/ to 4-2 Ddetasseler toolbar slide switch (if equipped) | Provides adjustment of the toolbar from 4-1 to 4-2 row configurations if equipped |

| C | Traction valve switch | Enables the machine traction control system for 30 seconds |

| D | Ignition switch | Engages engine starter to start the machine |

| E | Power mirror switch (if equipped) | The power mirror switch allows vertical or horizontal adjustment of the electric side- view mirrors by pressing the switch in the desired position. |

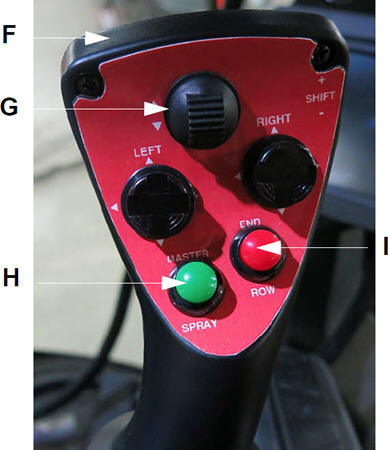

| F | Hydrostatic drive control handle | The hydrostatic drive control handle controls the direction of the machine and the speed in which it travels. It is also used to control the toolbar, master control, end row management, and shift up/down speeds. |

| G | All up/down switch | All up/down switch is used to raise or lower all row units at the same time. |

| H | Main control switch | Controls the on/off state of the detasseling motors |

| I | End row management switch | The end-row management switch is a programmable switch that enables various functions (i.e., all-wheel steerAWS, auto steer, master control) when the switch is depressed. End-row management settings are programmed through the machine display. |

| J | Shift up switch | The shift up/down switches are used for speed range selection. |

| K | Shift down switch | The shift up/down switches are used for speed range selection. |

| L | Parking brake switch | The parking brake switch is used to engage and disengage the parking brake, as well as extend and retract the ladder. |

| M | Throttle switch | The throttle switch is used to control engine speed (rpm). |

| N | 12-V power ports | Four power ports are provided for the connection of additional items (such as radios and computer equipment). |

| O | Two auxiliary audio input connections | The auxiliary audio input allows connection of a personal device or MP3 player. |

Front console

| Location (image) | Component | Description/notes |

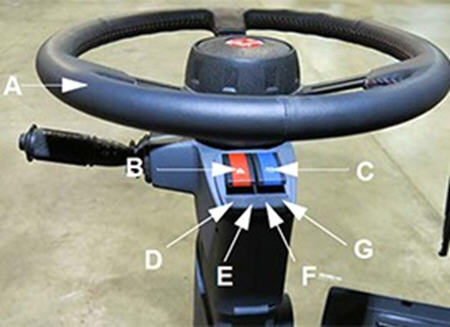

| A | Steering wheel | Optional premium leather-wrapped steering wheel |

| B | Hazard/warning lights switch | --- |

| C | Highway running lights switch | --- |

| D | Turn signal indicator | Left-hand side |

| E | Highway running lights indicator | --- |

| F | High beams indicator | --- |

| G | Turn signal indicator | Right-hand side |

| H | Steering wheel telescope adjust handle | Available only if equipped with this option |

| I | Steering column tilt adjust button | Knee angle |

| J | Steering column release pedal | --- |

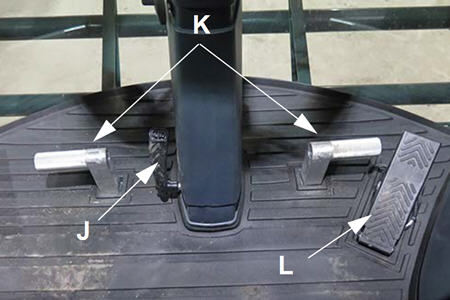

| K | Operator foot pegs | Two pegs |

| L | Deceleration (decel) pedal | --- |

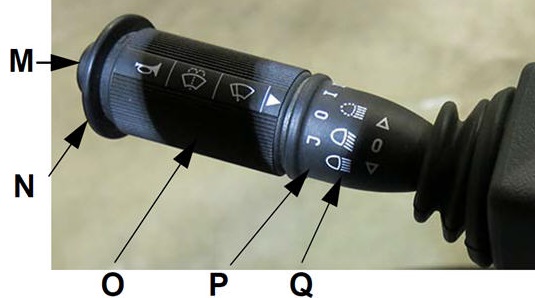

| M | Horn | --- |

| N | Windshield washer | --- |

| O | Turn signal lever | --- |

| P | Windshield wiper speed | --- |

| Q | High beams (brights) | --- |

iPod is a trademark of Apple Inc. Bluetooth is a trademark of Bluetooth SIG, Inc.

Frame and axles

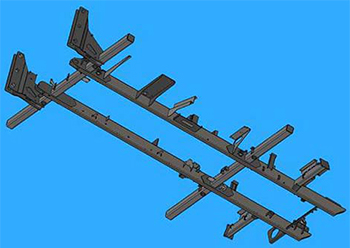

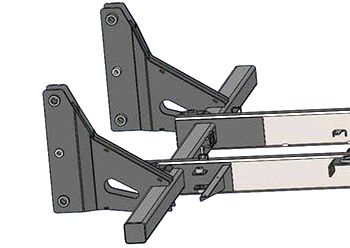

Chassis mainframe

Chassis mainframe

Horizontal cross-through axle tube

Horizontal cross-through axle tube

The D400 Detasseler mainframe design features horizontal cross-through axle tubes, as well as toolbar and platform mounts on weldment.

- 360.7-cm (142-in.) mainframe width

- 182.9-cm (72-in.) ground clearance