Online Brochures

Overview

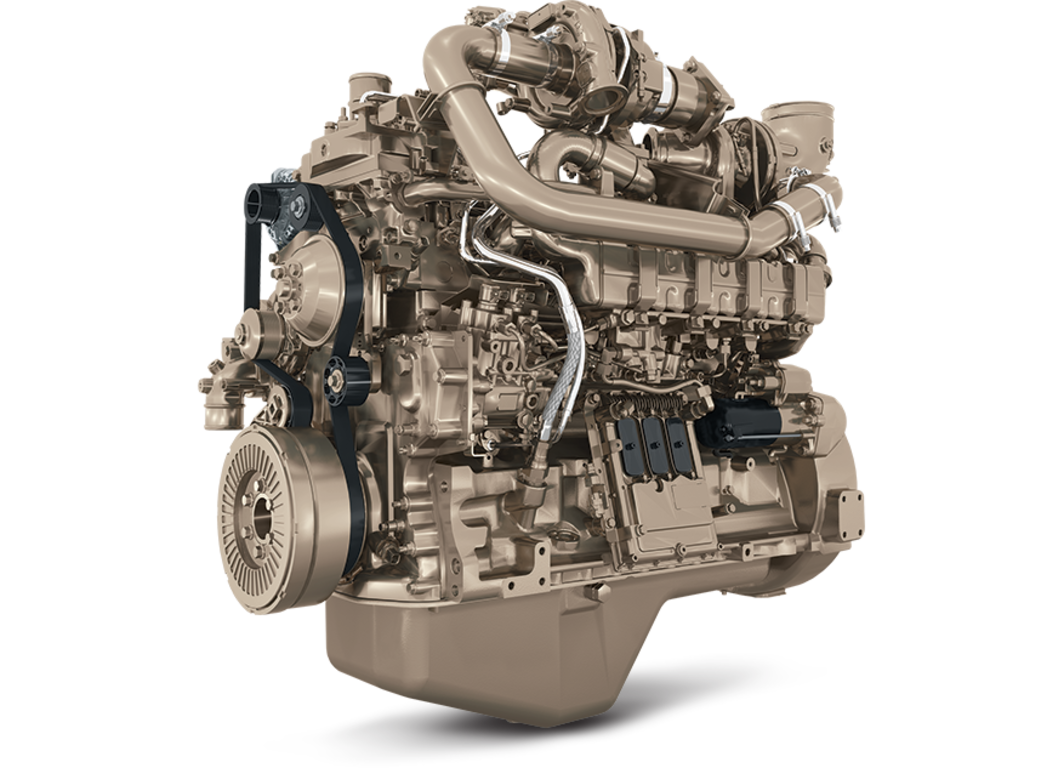

- PowerTech™ PVS

- 104-187 kW (140-250 hp) @ 2000-2400 RPM

- Continuous, Heavy Duty, Intermittent

Features

Features

Features

Expand All

Collapse All

Stage V.

- John Deere has billions of hours of field experience with off-highway diesel engine technologies and launched many of its engines ahead of EPA and EU deadlines, and is ready to meet Stage V emissions regulations using our proven diesel particulate filter (DPF) solutions. In most cases, OEM customers currently using a John Deere engine with a diesel particulate filter (DPF) won’t have to re-engineer machine design to meet the requirements of Stage V regulations. Our engineers continue to employ a global network of technical resources and the latest technology to lower emissions while improving performance and fluid efficiency.

Variable geometry turbocharger (VGT)\

- Varies exhaust pressure based on load and speed to ensure proper EGR flow. The combination of the cooled EGR and VGT provide low-speed torque, quicker transient response, higher-peak torque, and world-class fuel economy.

Exhaust filters

- These engines utilize a catalyzed exhaust filter that contains a diesel oxidation catalyst (DOC) and a diesel particulate filter (DPF). The DOC reacts with exhaust gases to reduce carbon monoxide, hydrocarbons, and some particulate matter (PM). The downstream DPF traps and holds the remaining PM. Trapped particles are oxidized within the DPF through a continuous cleaning process called passive regeneration. Passive regeneration occurs during normal operating conditions when heat from the exhaust stream, and catalysts within the exhaust filter, trigger the oxidation of the trapped PM. If passive regeneration cannot be achieved due to low temperature, load, or speed, then PM is removed using active regeneration — an automatic cleaning process controlled by the exhaust temperature management system.

Cooled exhaust gas recirculation (EGR)

- EGR cools and mixes measured amounts of cooled exhaust gas with incoming fresh air to lower peak combustion temperatures, thereby reducing Nox.

Selective catalytic reduction (SCR)

- John Deere engines feature an SCR system that utilizes a urea-based additive, sometimes referred to as diesel exhaust fluid (DEF) to meet Stage V emission standards. A chemical reaction in the SCR catalyst converts urea and NOx emissions into nitrogen and water vapor.

High-pressure common-rail (HPCR)

- The HPCR fuel system provides variable common-rail pressure and high injection pressures. It also controls fuel injection timing and provides precise control for the start, duration, and end of injection.

Air-to-air aftercooled

- This is the most efficient method of cooling intake air to help reduce engine emissions while maintaining low-speed torque, transient response time, and peak torque. It enables an engine to meet emissions regulations with better fuel economy and the lowest installed costs.

4-valve cylinder head

- The 4-valve cylinder head provides excellent airflow resulting in excellent low-speed torque and transient response.

Compact size

- Lower installed cost

- Mounting points are the same as previous engine models

John Deere electronic engine controls

- Faster engine control unit (ECU) manages both the engine and the exhaust filter

- Premium software option integrates with equipment or vehicles to reduce engineering and installation costs

Big-engine durability

- Replaceable (wet) cylinder liners

- Oil-cooled pistons with hardened ring groove insert

- Full flow engine-mounted oil cooler

- Up to 500-hour oil change

Additional features

- Glow Plugs cold start aid

- Engine or remote mounted fuel filters

- Gear-driven auxiliary drives

- Self-adjusting poly-vee fan drive with optional variable-speed fan

- Optional electric fuel transfer pump with “auto-prime” feature

Share: