Online Brochures

Overview

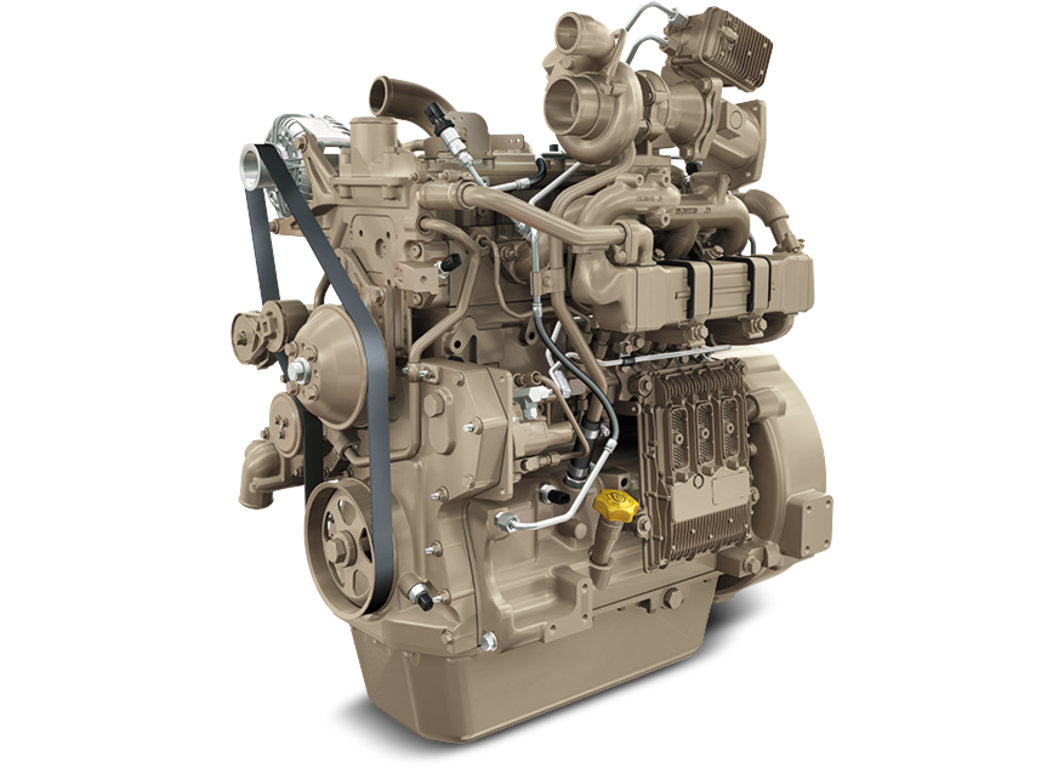

- PowerTech™ PW

- 63 - 102 kW (84 - 137 hp)

Features

Features

Features

Expand All

Collapse All

Wastegated turbocharger

- Wastegated turbochargers are designed to develop more air flow at lower engine speeds to improve low speed torque. The wastegate control device bleeds off a portion of the exhaust flow at higher engine speeds. Wastegated turbos deliver improved transient response and higher peak torque without compromising engine envelope size. They also provide the lowest installed cost across a given power range.

Cooled exhaust gas recirculation (EGR)

- EGR cools and mixes measured amounts of cooled exhaust gas with incoming fresh air to lower peak combustion temperatures, thereby reducing Nox.

Exhaust filters

- These engines utilize an exhaust filter that contains a diesel oxidation catalyst (DOC) and a particulate filter. The DOC reacts with exhaust gases to reduce carbon monoxide, hydrocarbons, and some particulate matter (PM).

- The downstream filter traps and holds the remaining PM. Trapped particles are oxidized within the filter through a continuous cleaning process called passive regeneration. Regeneration occurs during normal operating conditions when heat from the exhaust stream and catalysts within the exhaust filter trigger the oxidation of the trapped PM.

High-pressure common-rail (HPCR) and engine control unit (ECU)

- The HPCR fuel system provides variable common-rail pressure and higher injection pressures up to 1,975 bar (29,000 psi).One ECU controls the exhaust filter, as well as fuel system and provides precise control for the start, duration, and end of injection.

4-valve cylinder head

- The 4-valve cylinder head provides excellent airflow resulting in greater low-speed torque and better transient response time by utilizing a cross-flow design.

Air-to-air aftercooled

- This is the most efficient method of cooling intake air to help reduce engine emissions while maintaining low-speed torque, transient response time, and peak torque. It enables an engine to meet emissions regulations with better fuel economy and the lowest installed costs.

Compact size

- Lower installed cost

- Mounting points are the same as previous engine models

Engine performance

- Multiple rated speeds to further reduce noise and improve fuel economy

- Higher level of peak torque

- Low-speed (1000 rpm) torque equal to or better than Tier 3/Stage III A

- Optional power bulge equal to or better than Tier 3/Stage III A

Electronic engine controls

- Faster engine control unit (ECU) manages both the engine and the exhaust filter

- Four times the memory, twice the RAM, and double the processing speed

- The input/output capability has increased 40%

- JDLink™ lets you monitor, protect, and maintain your equipment 24/7

- Premium software option integrates with equipment or vehicles to reduce engineering and installation costs

Additional features

- Glow Plugs

- Gear-driven auxiliary drives

- 500-hour oil change

- Optional factory installed variable-speed fan drive improves fuel economy and reduces noise levels

- R.H. and L.H. engine-mounted final fuel filters

- Optional low-pressure fuel system with electrical transfer pump and "auto-prime" feature

Share: