Online Brochures

Overview

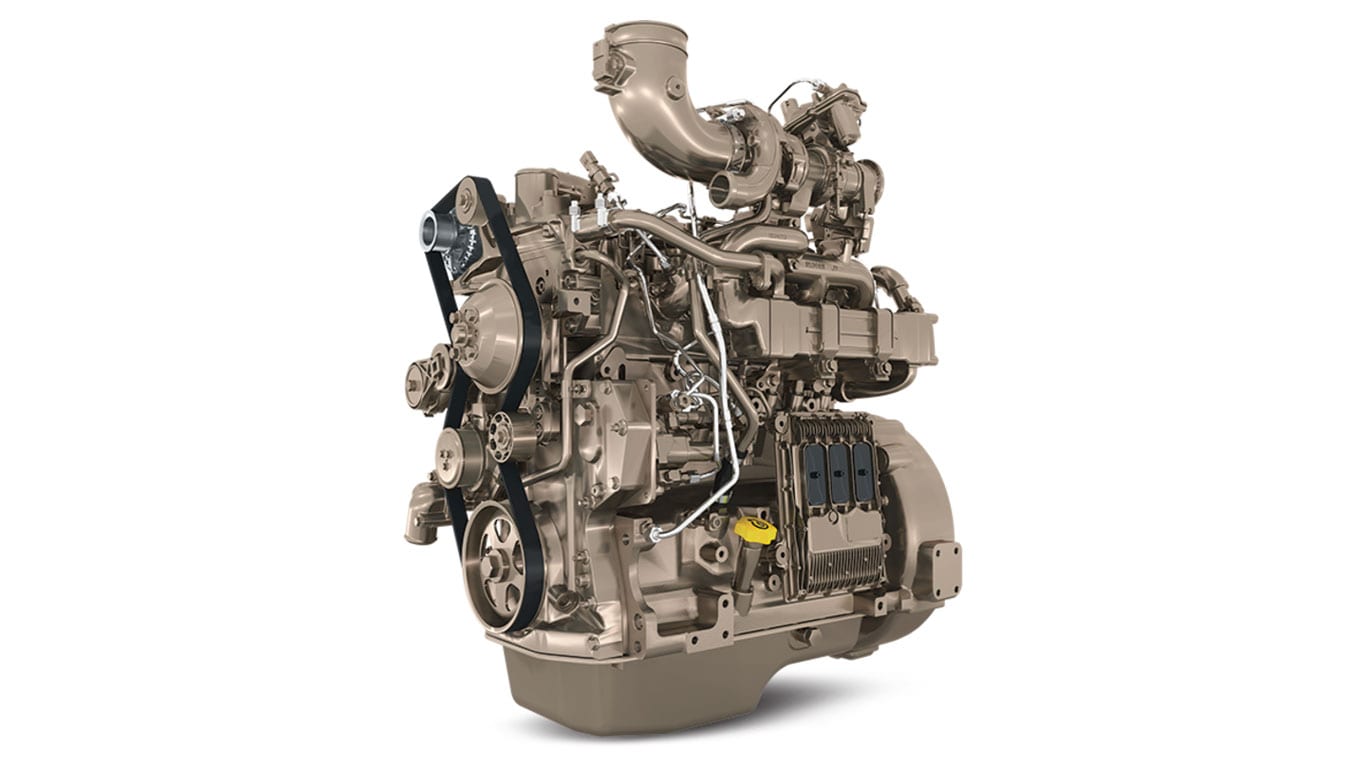

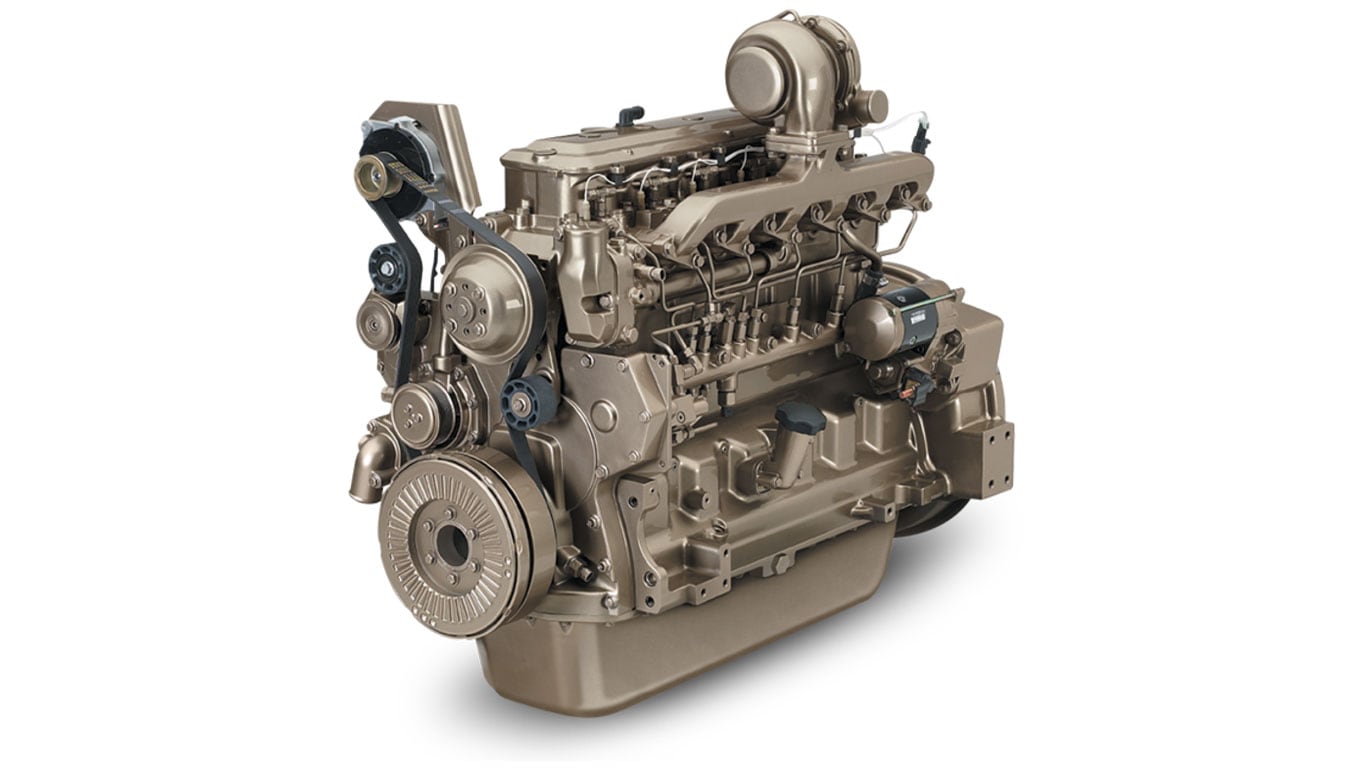

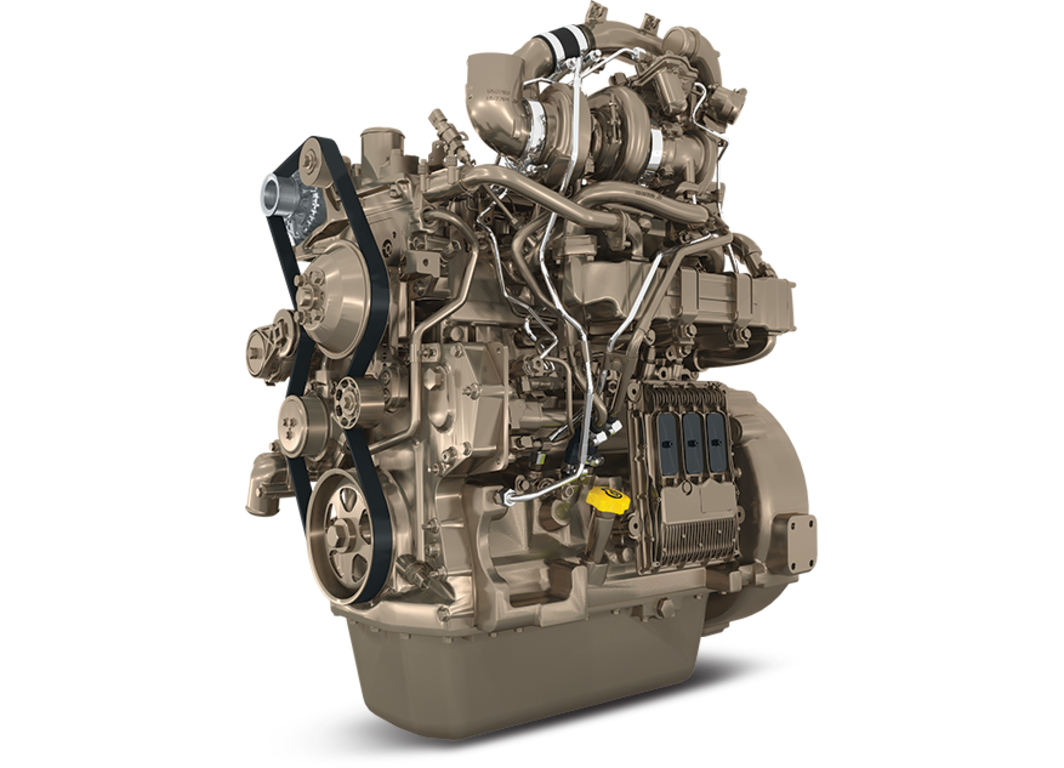

- PowerTech™ PSL

- 93-129 kW (125-173 hp)

Features

Features

Features

Expand All

Collapse All

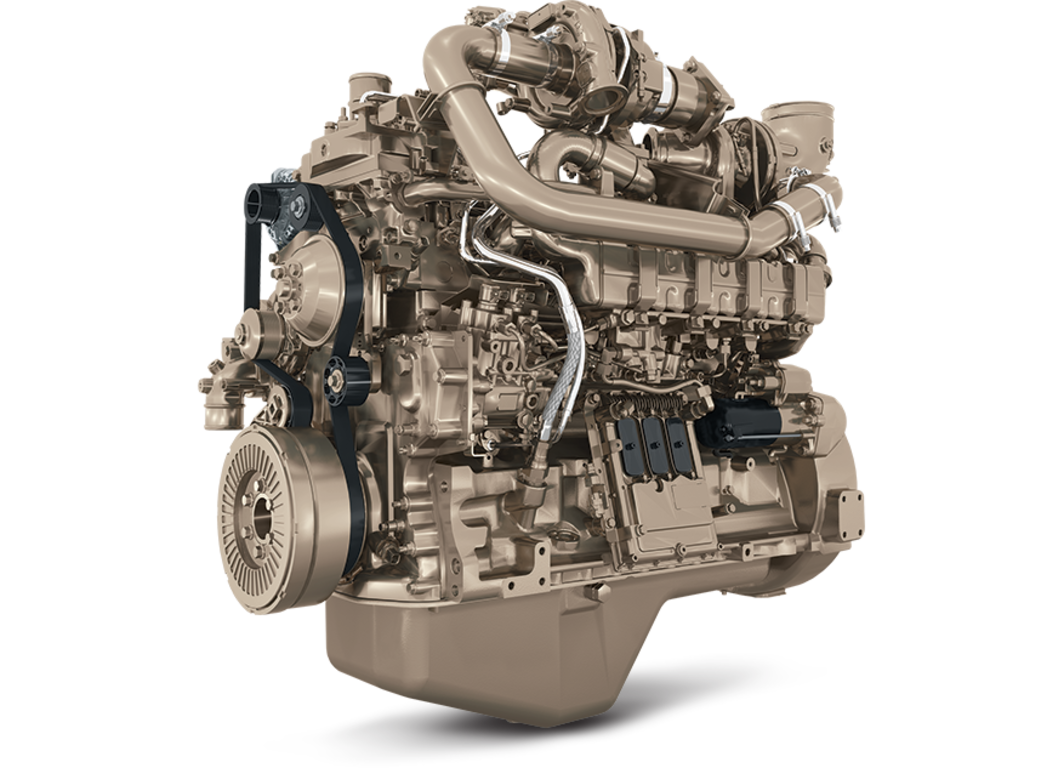

Series turbocharger

- Fresh air is first drawn into the low-pressure turbocharger (fixed geometry) and compressed to a higher pressure. The compressed air is then drawn into the high-pressure turbocharger (VGT or WGT), where the air is further compressed. The high-pressure air is then routed through a charge air cooler and into the engine’s intake manifold. By splitting the work between two turbochargers, both can operate at peak efficiency and at slower rotating speeds — lowering stress on turbocharger components and improving reliability. Series turbocharging delivers more boost pressure than single turbocharger configurations, which results in higher power density, improved low-speed torque, and improved high-altitude operation

Cooled exhaust gas recirculation (EGR)

- EGR cools and mixes measured amounts of cooled exhaust gas with incoming fresh air to lower peak combustion temperatures, thereby reducing Nox.

Diesel oxidation catalyst (DOC) and selective catalytic reduction (SCR)

- Diesel Oxidation Catalyst (DOC) and Selective Catalytic Reduction (SCR)

- These engines utilize a catalyzed exhaust filter that contains a diesel oxidation catalyst (DOC). The DOC reacts with exhaust gases to reduce carbon monoxide, hydrocarbons, and some particulate matter (PM). John Deere engines feature an SCR system that utilizes a urea-based additive,sometimes referred to as diesel exhaust fluid (DEF). The ammonia in the urea mixes with engine exhaust gases in the SCR catalyst to reduce NOx — converting it to nitrogen and water vapor.

High-pressure common-rail (HPCR) and engine control unit (ECU)

- The HPCR fuel system provides variable common-rail pressure, multiple injections, and higher injection pressures up to 2,500 bar (36,000 psi). It also controls fuel injection timing and provides precise control for the start, duration, and end of injection.

4-valve cylinder head

- The 4-valve cylinder head provides excellent airflow resulting in greater low-speed torque and better transient response time by utilizing a cross-flow design.

Air-to-air aftercooled

- This is the most efficient method of cooling intake air to help reduce engine emissions while maintaining low-speed torque, transient response time, and peak torque. It enables an engine to meet emissions regulations with better fuel economy and the lowest installed costs.

Compact size

- Lower installed cost

- Mounting points are the same as previous models

Engine performance

- Multiple rated speeds to further reduce noise and improve fuel economy

- Peak torque equal to or better than Interim Tier 4/Stage III B

- Transient response time equal to Interim Tier 4/Stage III B

- Low-speed torque similar to Interim Tier 4/Stage III B

John Deere electronic engine controls

- Faster engine control unit (ECU) manages both the engine and the aftertreatment system

- Four times the memory, twice the RAM and double the processing speed

- The input/output capability has increased 40%

- Premium software option integrates with equipment or vehicles to reduce engineering and installation costs

Additional features

- Glow plugs

- Air-grid heater

- Gear-driven auxiliary drives

- 500-hour oil change

- Self-adjusting poly-vee fan drive

- Optional factory installed variable-speed fan drive improves fuel economy and reduces noise levels

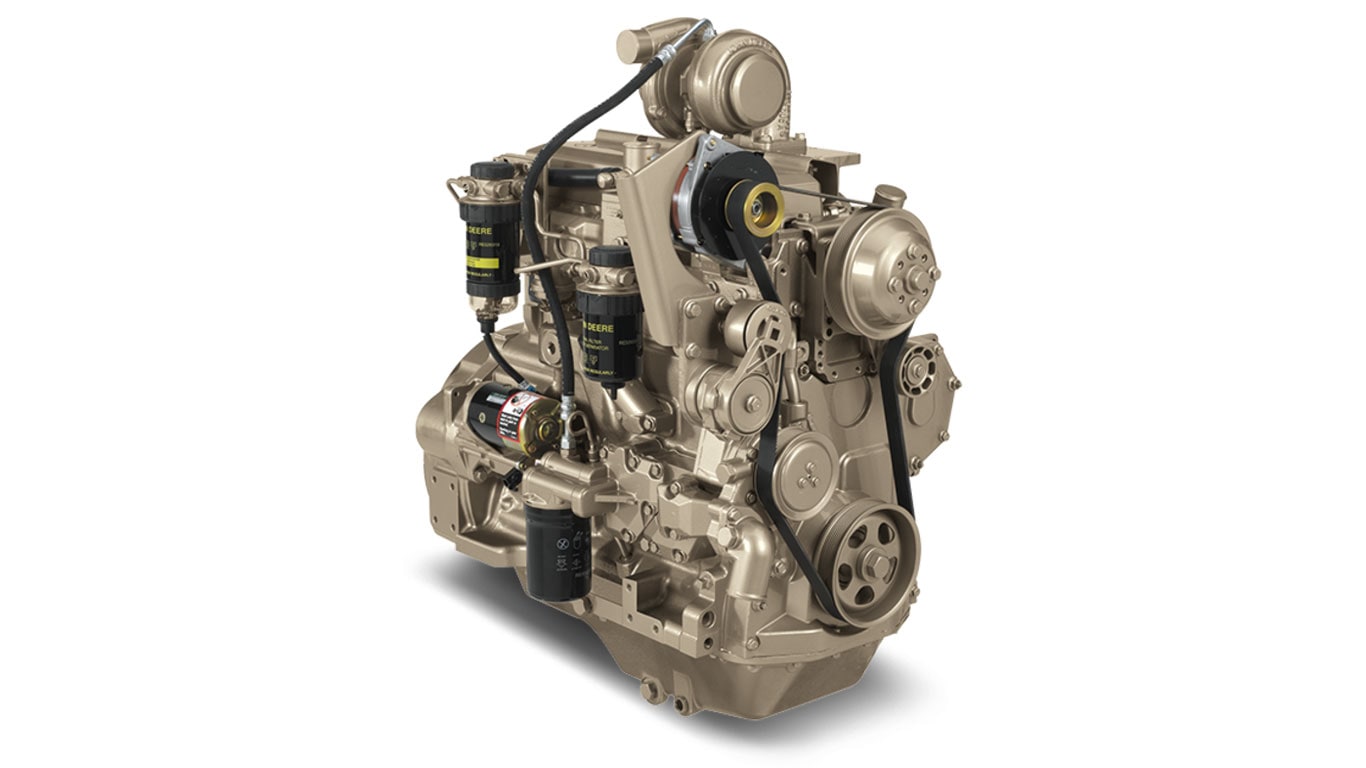

- R.H. or L.H. engine-mounted fuel filters

- Low-pressure fuel system with electrical transfer pump and "auto-prime" feature

Share: