Overview

- Working widths from 25ft, 6 in. to 69 ft, 6 in. (7.8 to 21.2 m)

- Follows ground contour, stays level

- Lattice-style frame design

- Hydraulically adjustable rolling baskets

Features

Features

Wide range of working widths available to match acreage and horsepower requirements

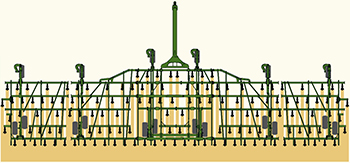

Three-section configuration

Three-section configuration

Five-section configuration

Five-section configuration

At 16-km/h (10-mph) working speeds, the 2230FH can cover up to 34 ha (84 acres) per hour, enabling producers to size their implement for their unique productivity and agronomic needs.

The 2230FH is available in sizes ranging from 7.8 to 21.2 m (25 ft, 6 in. to 69 ft, 9 in.). Horsepower requirements range from 19.6-29.4 kw/m (8 to 12 hp-ft), depending on the soil, depth, and speed.

Three-section configurations

| Working widths | Centerframe size | Productivity per hour at 16 km/h (10 mph) |

| 7.77 m (25 ft, 6 in.) | 3.4 m (11 ft) | 12.5 ha (31 acres) |

| 8.99 m (29 ft, 6 in.) | 14.6 ha (36 acres) | |

| 9.60 m (31 ft, 6 in.) | 15.4 ha (38 acres) | |

| 10.21 m (33 ft, 6 in.) | 16.6 ha (41 acres) | |

| 10.82 m (35 ft, 6 in.) | 17.4 ha (43 acres) | |

| 12.95 m (42 ft, 6 in.) low transport |

21.0 ha (52 acres) |

Five-section configurations

| Working widths | Centerframe size | Productivity per hour at 16 km/h (10 mph) |

| 12.34 m (40 ft, 6 in.) | 3.4 m (11 ft) | 19.8 ha (49 acres) |

| 13.56 m (44 ft, 6 in.) | 21.9 ha (54 acres) | |

| 14.78 m (48 ft, 6 in.) | 23.9 ha (59 acres) | |

| 16.00 m (52 ft, 6 in.) | 25.9 ha (64 acres) | |

| 17.22 m (56 ft, 6 in.) | 27.5 ha (68 acres) | |

| 18.44 m (60 ft, 6 in.) | 29.5 ha (73 acres) | |

| 18.44 m (60 ft, 6 in.) | 4.6 m (15 ft) | 29.5 ha (73 acres) |

| 19.66 m (64 ft, 6 in.) | 31.6 ha (78 acres) | |

| 21.18 m (69 ft, 6 in.) | 34.0 ha (84 acres) |

Floating hitch frame keeps implement level across varying terrain

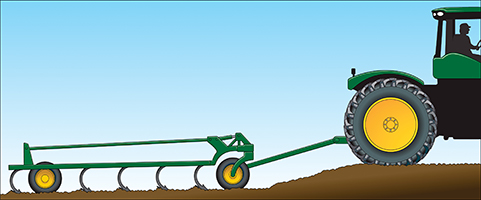

Floating hitch frame on 2230FH

Floating hitch frame on 2230FH

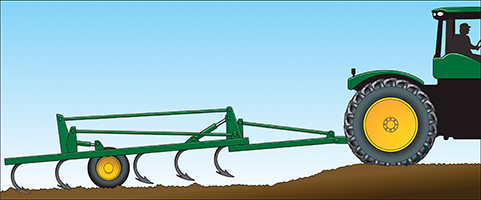

Level-lift hitch frame on 2230LL

Level-lift hitch frame on 2230LL

The 2230FH Floating Hitch Field Cultivator offers superior ground-hugging capability with precise depth and pressure control across all types of terrain. The floating hitch frame design enables this field cultivator to work independently of the tractor and follow the contour of the ground so the implement remains level. The 2230FH commands consistent depth from front to back and from side to side.

True 152-mm (6-in.) split-the-middle spacing provides complete field coverage

TruPosition™ standards on 2230 Field Cultivator

TruPosition™ standards on 2230 Field Cultivator

152-mm (6-in.) split-the-middle shank spacing

152-mm (6-in.) split-the-middle shank spacing

Thanks to an updated frame design that enables true 152-mm (6-in.) split-the-middle shank spacing, the 2230 Field Cultivators can maintain consistent depth and evenly cover the field to achieve an optimal seedbed and manage weeds.

Seedbed preparation

Even at high speeds and in tough field conditions, the TruPosition C-shanks with 91 kg (200 lb) of trip force minimize side-to-side movement and provide the operator better control of the soil profile for improved leveling capabilities.

These shanks provide a full tillage cut across the entire width of the implement. The shanks stay firmly planted in tough soils without quickly relieving. As a result, the soil is mixed completely and streaks are reduced. This helps producers maximize their productivity and create flat seedbeds for smooth planter operation and consistent seed depth.

Weed management

The even 152-mm (6-in.) split-the-middle shank spacing enables the 2230 Field Cultivator to minimize the potential of remaining strips of weeds that survive the tillage pass. With a field cultivator pass just prior to planting/seeding, the crop can emerge into a weed-free field that gives it the best chance to reach canopy ahead of the weeds.

If some weeds emerge and a post-emergence herbicide is needed, weeds should be smaller and easier to control. As a result, the field cultivator pass helps keep weed management costs under control and helps preserve crop yield potential.

Spacing options

True 152-mm (6-in.) split-the-middle spacing

True 152-mm (6-in.) split-the-middle spacing

152-mm (6-in.) shank spacing base equipment on the 2230LL and 2230FH. Additional options for implement customization include:

- 229-mm (9-in.) shank spacing

- 114-mm (4.5-in.) s-tine spacing (on select configurations)

Variety of sweeps provide solutions for all soil conditions

Bolt-on, knock-on, and s-tine sweep options are available to customize the 2230 Field Cultivators to perform well in a variety of field conditions.

| Bolt-on sweeps | Knock-on sweeps | S-tine sweeps* | ||||

| Tru-Width™ | High productivity | Perma-Loc™ | Perma-Loc high productivity | Wide S-tine | V-pattern S-tine | |

| 152-mm (6-in.) spacing | X | X | X | X | --- | --- |

| 229-mm (9-in.) spacing | X | X | X | X | --- | --- |

| 114-mm (4.5-in.) spacing | --- | --- | --- | --- | X | X |

*NOTE: S-tine sweeps not available for all 2230 configurations.

John Deere’s high-productivity sweep options are recommended for the high-working-speed market and perform best at speeds of 11-16 km/h (7-10 mph). With a low profile and curved wing shape, the high-productivity sweeps provide low draft and consistent penetration while easily getting through tough and heavy residue. Compared to Tru-Width sweeps, high-productivity sweeps are designed to exert less draft and retain their shape for longer wear life so producers can stay productive in the field longer.

The high-productivity sweeps are available bolt-on and the knock-on Perma-Loc versions. They fit all 47-degree standards with 44-mm (1.75-in.) hole spacing and 11 mm (0.4375 in.) that currently take Tru-Width sweeps, both John Deere and other makes.

Bolt-on sweeps

The Tru-Width design offers the following benefits:

- Maintains full cutting width and point through the life of the sweep

- Gives greater wear life and improved performance over regular sweeps

- Provides superior scouring and penetration

- Works soil well for level seedbed and good seed-to-soil contact

- Gives excellent chemical incorporation

- Wears evenly and pulls easily

- Replacement without charge if breakage occurs before appreciable wear

Knock-on sweeps

Perma-Loc sweep

Perma-Loc sweep

High-productivity Perma-Loc sweep

High-productivity Perma-Loc sweep

Perma-Loc utilizes a self-tightening ratcheting system for easy installation. Indentations formed in the sweep stem provide the spring clip with a locking surface. The adapter edge, sweep, and spring all act together to tightly lock the sweep to the shank. The operator simply pushes the sweep on by hand to the first notch (audible click). As the resistance is increased (ground engagement), the sweep progressively wedges tighter. The mounting design minimizes lost sweeps and wear on adapter.

Utilizing the removal tool to depress the spring through the stem access opening and a tap with a hammer easily releases the sweep from the adapter and spring.

Perma-Loc sweeps have the advantage of using a Tru-Width design for penetration, residue flow, and long life. The proven 47-degree sweep angle minimizes soil slabbing yet promotes soil movement. The narrow stem enhances excellent soil and residue flow. Stem geometry ensures soil flow over the spring access opening, effectively separating and lifting flow to a point higher on the shank. The force of soil flow is reduced on the shank, improving shank life.

Tru-Width sweeps with the Perma-Loc adapter can seamlessly move the high-productivity sweeps. The high-productivity sweeps use the current Perma-Loc adapter for 47-degree curved standard, N237614.

ProFinish™ Leveling System offers wide range of rear harrows to meet agronomic needs

The ProFinish Leveling System offers a wide range of rear harrows to meet agronomic needs.

Depending on agronomic needs, producers have a choice of six rear harrow options included in the ProFinish Leveling System on the 2230 Field Cultivators.

| Capabilities | 4-bar coil-tine harrow | 6-bar spike-tooth harrow | 3-bar coil-tine with round-bar basket | 3-bar coil-tine with flat-bar basket | 3-bar spike-tooth with round-bar basket | 3-bar spike-tooth with flat-bar basket |

| Level seedbed | Good | Better | Best | Best | Best | Best |

| Firm seedbed | Fair | Good | Best | Better | Best | Better |

| Handle residue | Best | Better | Best | Best | Better | Better |

| Break up clods | Good | Better | Better | Best | Better | Best |

| Handle moisture/wet soil | Best | Better | Good | Good | Good | Good |

| Handle rocks | Best | Good | Better | Good | Better | Good |

TruSet™ Tillage provides precise depth and pressure control from the cab on the go

TruSet and single-point depth control

TruSet and single-point depth control

TruSet controller

TruSet controller

Integrated TruSet Tillage technology enables field cultivator operators to adjust sweep depth and down pressure on the active hydraulic rolling baskets while on the go to respond to changing field conditions such as varying soils, heavier residue, and moisture.

With short window of time to perform tillage operations, TruSet can provide significant productivity improvements as operators are able to adjust the field cultivator while covering acres with the push of a button. By responding to conditions as they change throughout the field, TruSet enables operators to generate better-quality tillage performance with the first pass.

Using a GreenStar™ display, a user sees real-time data for sweep depth and basket down pressure for assurance of desired tillage outcomes. Once the actual set point is validated and configured to the display in the cab, operators are able to make independent adjustments as small as one tenth of an inch. Four customizable presets enable operators to save and name different combinations of settings for their most common field conditions.

Single-point depth control is included with the TruSet Tillage system, giving operators the choice of automated or manual adjustments. Hydraulic routings on the 2230 Field Cultivators are designed to allow each implement to feature both TruSet and standard single-point depth control for system redundancy, operator preference, and flexibility at resale.

Components

TruSet is compatible with John Deere and competitive tractors. Depending on the tractor, a compatibility kit may be needed in addition to the TruSet Tillage system. The following chart identifies the components needed to operate TruSet on a 2230LL or 2230FH Field Cultivator with a GreenStar ready tractor.

| TruSet product | John Deere 30 Series and newer Tractors |

John Deere 20 Series Tractors (large frame or IVT™ system) | John Deere 20 Series Tractors (small frame or non IVT) | John Deere 10 Series and older Tractors | Competitive tractors |

| TruSet Tillage system | Yes | Yes | Yes | Yes | Yes |

| TruSet compatibility kit | No | No | Yes | Yes | Yes |

Both the TruSet Tillage system and the compatibility kit will be available as a field-installed option that can be ordered with the field cultivator or through aftermarket parts.

All model years of the 2230LL and 2230FH can be retrofitted with TruSet.

TruSet Tillage requires a GreenStar ready tractor with a supported display. The TruSet Tillage system must have a connection to the tractor ISO connection. Additional TruSet Tillage information:

TruSet™ Side-to-Side feature provides individual section leveling on 2230FH Floating Hitch Field Cultivator

2230FH Floating Hitch Field Cultivator operators have the option to enhance the TruSet Tillage system with individual section leveling functionality. TruSet Side-to-Side will be available as a field-installed option that can be ordered with the 2230FH or through aftermarket parts. The base TruSet Tillage system can also be upgraded to TruSet Side-to-Side on the 2230FH with a conversion kit.

Functionality by depth control option

| Single point | TruSet | TruSet Side-to-Side | |

| One adjustment to change implement depth | X | X | X |

| Mechanical adjustment option | X | X | X |

| In-cab adjustment option | --- | X | X |

| In-cab individual section leveling | --- | --- | X |

| Tillage documentation and prescription | --- | X | X |

Tillage documentation and prescription functionality included with TruSet™ Tillage

With integrated TruSet Tillage technology, 2230 Field Cultivator operators can incorporate documentation and prescription functionality into their tillage operations. The tillage documentation feature will give producers the ability to capture and analyze the field cultivator pass for additional coverage of the crop production cycle. Prescription functionality provides producers the capability to ensure their tillage operations are executed correctly, optimizing their investment in preparing for the next crop.

Operators can document data for the depth of their field cultivator sweeps along with rolling basket down pressure. By creating an as-applied map based off of global positioning system (GPS) data for the job performed by each functional area on the implement, TruSet enables producers to document their tillage passes then later review and analyze the data for future agronomic decisions.

Additionally, the Prescription Creator by Agrian® company, a connected partner tool through the John Deere Operations Center, enables producers to create prescriptions for each functional area on the 2230 Field Cultivators. Data from previous yields, soil surveys, or freehand drawing tools can be used to create prescriptions that will command the implement to the desired depth and pressure settings for optimum agronomic results.

Agrian is a trademark of Agrian, Inc.

Active-hydraulic castering wheels facilitate excellent turning

Active-hydraulic castering wheel

Active-hydraulic castering wheel

Castering wheels on 2230FH

Castering wheels on 2230FH

Front-mounted active-hydraulic castering depth-control wheels come standard on the 2230FH Floating Hitch Field Cultivator’s centerframe and wings. These active-hydraulic castering wheels rotate a full 360 degrees and provide good stability at the front of the implement and facilitate excellent turning, reducing tire scuffing.

Working together with John Deere’s floating hitch, the active-hydraulic castering wheels help ensure level operation for the 2230FH as the implement is free to follow the contour of the terrain. This frame flexibility over rolling terrain provides more uniform depth integrity fore to aft for:

- Consistent sweep depth

- Thorough seedbed preparation through the entire width and length of the implement

- Consistent chemical placement and mixing

The active-hydraulic castering wheels can be manually adjusted with a turnbuckle. TruSet™ with side-to-side leveling capabilities also enables operators to individually control wing depth and the castering wheels from the cab while on the go.

Regular- and low-transport configuration available for 2230FH

Low-transport field cultivator

Low-transport field cultivator

Low power lines and bridges can be a concern when transporting equipment. The 2230 Field Cultivator lineup includes regular- and low-transport configurations as a solution for transportation concerns.

The 12.95-m (42-ft, 6-in.) 2230FH folds like a five-section implement, but operates like a three-section implement. A small wing is added to these implements. This allows them to have an extra fold to achieve the tight and narrow transport dimensions. When the implement is unfolded for operation, the small, outer-wings lock rigid to allow for three-section operation.

Another advantage of the low-transport models is operation in uneven terrain. The low-transport models allow for the rigid wing to follow the contour of the ground.

The regular-transport model features an 18.44-m (60-ft, 6-in.) working width on a 4.6-m (15-ft) mainframe that allows for a lower transport height compared to the other 18.44-m (60-ft, 6-in.) configuration.

| Configuration | Working width | Transport height | Transport width |

| Low transport | 12.95 m (42 ft, 6 in.) | 4.22 m (13 ft, 10 in.) | 5.33 m (17 ft, 6 in.) |

| Regular transport | 18.44 m (60 ft, 6 in.) | 4.75 m (15 ft, 7 in.) | 7.16 m (23 ft, 6 in.) |